In the rapidly evolving landscape of modern manufacturing, precision machining stands out as a pivotal force driving innovation and efficiency. As industries increasingly demand high levels of accuracy and customization, the role of precision machining becomes paramount in meeting these expectations. This advanced technique leverages cutting-edge technology and skilled craftsmanship to produce intricate components with unparalleled precision, which is essential for modern applications ranging from aerospace to medical devices. By exploring the transformative impact of precision machining on manufacturing processes, this guide will demonstrate how it not only enhances product quality but also accelerates production times and reduces costs. As we delve into the various aspects of this sophisticated method, we will uncover the principles and practices that are at the forefront of manufacturing innovation, ultimately revealing how precision machining is reshaping the future of the industry.

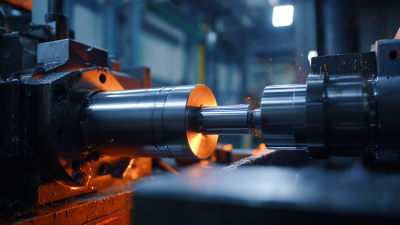

Precision machining is a cornerstone of modern manufacturing, fundamentally transforming how products are designed and built. This technique involves the removal of material from a workpiece to achieve very tight tolerances and high-quality finishes. According to a report by the American Society of Mechanical Engineers (ASME), industries that employ precision machining can achieve up to 50% time savings in production cycles. By utilizing advanced computer numerical control (CNC) machines, manufacturers gain the ability to produce complex geometries with unparalleled accuracy, leading to reduced waste and increased efficiency.

**Tip:** When considering precision machining for your manufacturing needs, ensure your design takes full advantage of the capabilities of CNC equipment. This can significantly cut down production costs and improve lead times.

Moreover, the integration of precision machining with automation technologies is paving the way for smarter manufacturing ecosystems. Research by the National Institute of Standards and Technology (NIST) indicates that automation in precision machining can enhance output by 30-40%, while also minimizing human error. As manufacturers adopt Industry 4.0 principles, the synergy between precision machining and smart technologies will only continue to grow, fostering innovation and sustaining competitiveness in the global market.

**Tip:** Embrace continuous training and development for your workforce to keep pace with the advancements in precision machining technologies. Staying informed ensures your team can leverage new capabilities and maintain high-quality output.

| Dimension | Description | Impact on Manufacturing |

|---|---|---|

| Accuracy | Precision machining technology enables extremely accurate cutting and shaping of materials. | Reduces waste and improves product quality. |

| Material Versatility | Capable of machining a wide variety of materials, including metals, plastics, and composites. | Allows manufacturers to produce a broad range of products with different material needs. |

| Efficiency | Advanced CNC machines automate and speed up the machining processes. | Increases production rates and reduces labor costs. |

| Surface Finish | Precision machining yields superior surface finishes compared to traditional methods. | Enhances the aesthetic and functional qualities of products. |

| Customization | Easily allow for tailored designs and specifications based on client needs. | Enables businesses to meet specific requirements and stay competitive. |

Precision machining is at the forefront of modern manufacturing, leveraging advanced technologies to enhance efficiency and accuracy. One of the key technologies driving this innovation is computer numerical control (CNC) machining. CNC machines enable manufacturers to produce intricate designs with exceptional precision, reducing waste and leading to faster production times. This technology allows for automation in the machining process, where complex tasks can be completed with minimal human intervention, significantly increasing productivity.

Additionally, additive manufacturing, often referred to as 3D printing, complements precision machining by enabling rapid prototyping and small-batch production. This technology allows for the creation of complex geometries that would be challenging or impossible to achieve with traditional machining methods. By integrating additive processes, manufacturers can streamline operations and reduce lead times while maintaining high-quality standards. These advancements in technology not only enhance precision machining but also contribute to the overall evolution of manufacturing techniques, pushing industries towards a more innovative and sustainable future.

Precision machining techniques have become pivotal in improving product quality in modern manufacturing. By utilizing advanced machinery and tools, manufacturers can achieve high levels of accuracy and repeatability. This results in parts that fit perfectly and function effectively, reducing the likelihood of defects and enhancing overall product performance. For industries that rely on tight tolerances, such as aerospace and medical devices, precision machining is not just beneficial but essential.

Implementing these techniques requires an investment in both technology and training. CNC (Computer Numerical Control) machines play a vital role, enabling manufacturers to produce intricate designs with minimal human error. Additionally, adopting methods like automated quality control ensures that each component meets the required specifications. As manufacturers embrace precision machining, they not only enhance the quality of their products but also increase production efficiency and reduce waste, positioning themselves as leaders in a competitive market.

This chart illustrates the percentage improvement in various product quality metrics after implementing precision machining techniques in modern manufacturing processes.

The adoption of precision machining in modern manufacturing is facing several challenges that organizations must navigate to fully realize its potential. One significant hurdle is the integration of advanced technologies, particularly artificial intelligence (AI) and machine learning, which can enhance accuracy and efficiency. According to a report by the Manufacturing Institute, nearly 87% of manufacturers are unable to implement AI technologies due to outdated equipment and a lack of skilled workforce. This gap not only inhibits progress but also contributes to increased operational costs and delays in product delivery.

Moreover, there are challenges related to data management and quality, especially when integrating generative AI into manufacturing processes. Research indicates that poor data quality can lead to substantial losses, estimated at $3 trillion annually across various industries. To overcome these barriers, manufacturers need a strategic approach that includes

Precision machining is increasingly recognized for its pivotal role in advancing sustainable manufacturing practices. By leveraging advanced technologies such as CNC machining and additive manufacturing, companies can optimize resource use and minimize waste. These techniques allow for the production of high-precision components with minimal material consumption, reducing the overall environmental impact. As manufacturers strive to meet stringent sustainability targets, precision machining offers a pathway that balances efficiency with ecological responsibility.

Moreover, the shift towards sustainable manufacturing involves not just the techniques used but also the materials chosen. Precision machining allows for the integration of eco-friendly materials, such as biodegradable composites and recycled metals, into production processes. This capability not only lowers the carbon footprint but also enhances product lifecycle management. As the industry continues to innovate, the adoption of precision machining is set to play a crucial role in achieving a greener future for manufacturing, ensuring that productivity and sustainability go hand in hand.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources