In the rapidly evolving landscape of modern industries, precision instruments play an indispensable role in achieving measurement accuracy, which is crucial for quality control and operational efficiency. According to a report by MarketsandMarkets, the global precision measurement market is expected to reach $9.52 billion by 2025, underscoring the growing reliance on advanced measuring technologies across sectors like manufacturing, aerospace, and healthcare.

The precision of these instruments directly impacts product reliability and performance, with the potential to reduce errors and enhance productivity. Furthermore, a survey conducted by the NIST revealed that industries utilizing high-quality precision instruments experience up to a 30% decrease in production defects. As innovations continue to emerge, the demand for precision instruments will only intensify, solidifying their vital position in driving accuracy and success in the competitive industrial landscape.

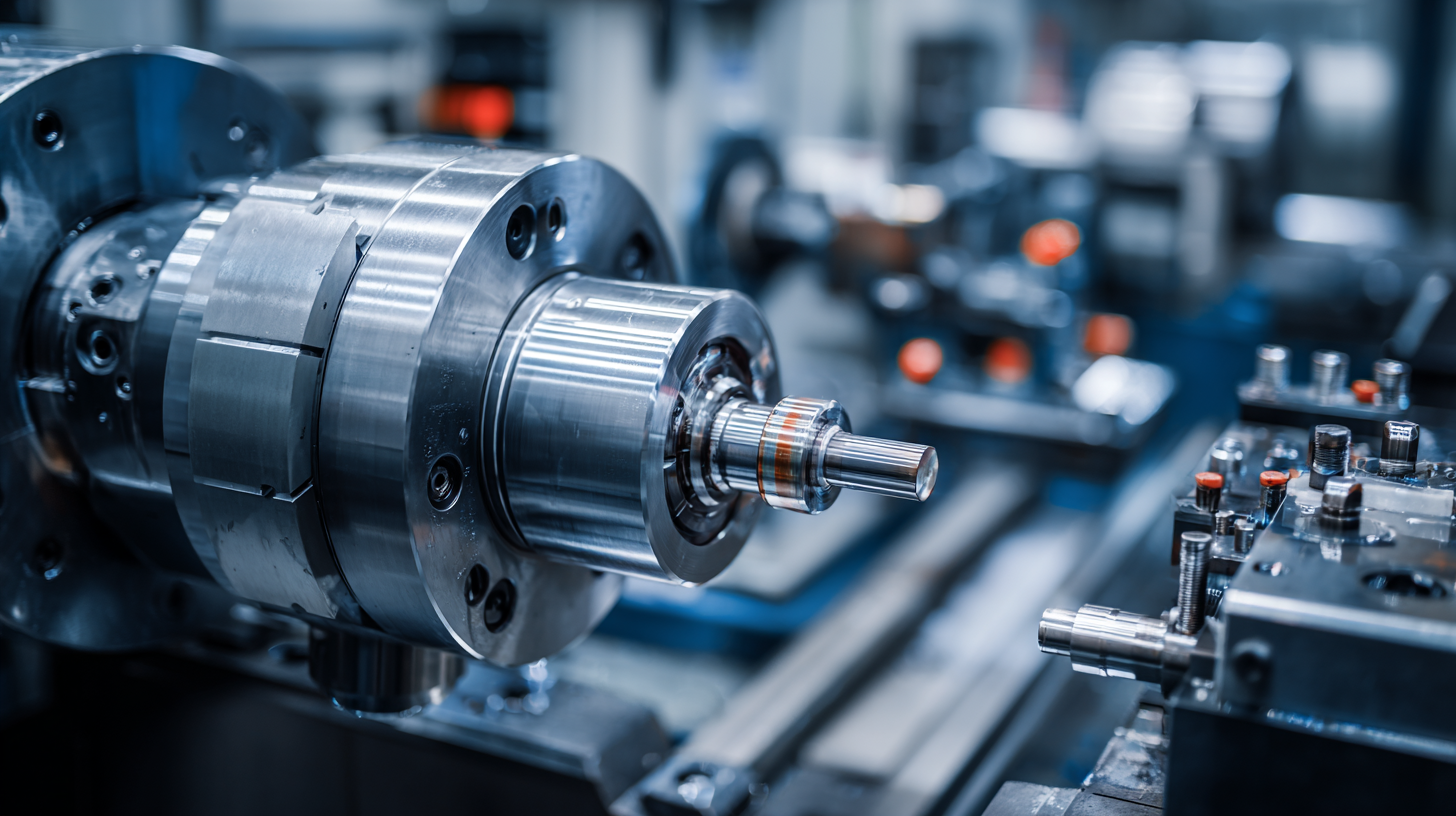

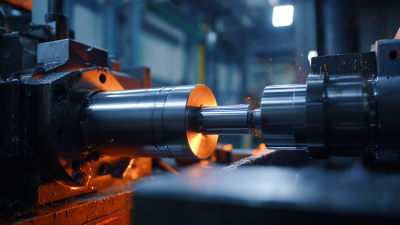

In modern industrial applications, precision instruments play an essential role in ensuring measurement accuracy. Industries ranging from manufacturing to aerospace rely on highly accurate instruments to produce high-quality products and maintain stringent safety standards. For example, in the production of aerospace components, even the slightest deviation in measurements can result in catastrophic failures. Therefore, precision instruments like micrometers, calipers, and laser measurement systems are critical in achieving the exact specifications required.

Moreover, the integration of precision instruments in industrial processes enhances efficiency and reduces waste. By providing accurate measurements, these instruments enable companies to optimize their operations, minimize errors, and improve the overall quality of their output. In fields such as pharmaceuticals, where dosages must be meticulously measured, precision is non-negotiable. As industries continue to embrace automation and advanced technologies, the need for precision instruments will only grow, underscoring their importance in achieving both operational excellence and compliance with regulatory standards.

Precision instruments play a vital role in ensuring measurement accuracy across various modern industries. These tools are designed to provide high levels of accuracy and repeatability, making them indispensable in sectors such as manufacturing, aerospace, and pharmaceuticals. For instance, calipers and micrometers are commonly used in manufacturing to measure dimensions with extreme precision, allowing for tight tolerances that are crucial for product quality.

In addition to traditional measurement tools, advanced technologies such as laser measurement systems and electronic gauges have gained prominence. Laser distance meters are particularly valuable in construction and engineering, as they offer quick and accurate distance measurements without the need for physical contact. Similarly, electronic weighing scales provide precise mass measurements necessary for the pharmaceutical industry, where dosage accuracy can significantly impact patient safety. The continuous advancement of precision instruments not only enhances measurement accuracy but also improves efficiency and productivity in various industrial applications.

Measurement accuracy is fundamental in ensuring product quality and safety across various industries. According to a report by the National Institute of Standards and Technology (NIST), a mere 1% measurement error can lead to over $1 billion in waste across the manufacturing sector annually. This statistic highlights how even small inaccuracies can accumulate, affecting not just the production process but also the final product's integrity, which may ultimately jeopardize consumer safety.

In the pharmaceutical industry, for instance, precise measurements are critical not only for dosages but also for ensuring compliance with regulatory standards. The U.S. Food and Drug Administration (FDA) mandates that any variance in measurements can result in significant fines or product recalls, which can amount to millions of dollars. A study conducted by the International Organization for Standardization (ISO) found that companies employing advanced precision instruments reported a 30% improvement in product reliability and a 25% decrease in safety-related incidents. Such data underscores the importance of adopting high-quality precision instruments in industries that prioritize accuracy to maintain product excellence and ensure the safety of consumers.

Recent advancements in precision measurement tools are driving significant changes across various industries. The integration of automation and the Internet of Things (IoT) has revolutionized the capabilities of Coordinate Measuring Machines (CMMs), making them essential for achieving high levels of accuracy and efficiency in manufacturing processes. These technological enhancements not only streamline operations but also ensure that measurements are consistently reliable, leading to improved product quality and reduced waste.

In parallel, China’s strategic initiatives to enhance its metrology capabilities set ambitious goals for 2030, particularly focusing on semiconductor and rare earth element precision. This push reflects a broader trend of investing in advanced measurement technologies to support key industries such as chip manufacturing and quantum computing. As these sectors evolve, the demand for precise measurement tools will continue to grow, highlighting the crucial role of modern precision instruments in fostering innovation and competitiveness on a global scale.

| Measurement Tool | Accuracy Level | Industry Usage | Technological Features |

|---|---|---|---|

| Digital Caliper | ±0.02 mm | Manufacturing, Engineering | Digital Display, Metric/Inch Conversion |

| Laser Interferometer | ±0.1 µm | Metrology, Aerospace | High Precision, Non-Contact Measurement |

| Coordinate Measuring Machine (CMM) | ±0.1 mm | Automotive, Aerospace | Automated Measuring, CAD Integration |

| Optical Comparator | ±0.5 µm | Quality Control, Manufacturing | Optical Magnification, Integrated Data Analysis |

| Electronic Balance | ±0.001 g | Laboratory, Food Industry | Digital Readout, Taring Function |

Achieving accurate measurements in modern industries presents several challenges, primarily stemming from variations in environmental conditions, equipment limitations, and the complexity of the materials being measured. For instance, temperature fluctuations can impact the calibration of precision instruments, leading to significant discrepancies in data. Furthermore, human error during measurement processes or misinterpretation of instrument readings can adversely affect the overall accuracy. These challenges necessitate the development of robust methodologies for precise measurements.

To address these issues, industries are increasingly adopting innovative solutions, such as automated calibration systems and advanced sensor technologies that can adapt to changing conditions. Implementing rigorous training programs for operators ensures that they are equipped to handle sophisticated measurement tools effectively. Moreover, real-time monitoring systems can provide immediate feedback, allowing for quick adjustments and verifying the accuracy of measurements. By investing in these solutions, industries can significantly enhance their measurement accuracy, ultimately leading to improved product quality and operational efficiency.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources