In the realm of modern manufacturing and automation, the emergence of innovative industrial solutions is reshaping the landscape and driving unprecedented progress. As industries face the dual challenges of increasing productivity and sustainability, these transformative strategies offer a pathway to enhanced efficiency and adaptability. This article delves into the various approaches and technologies that are revolutionizing traditional manufacturing processes, paving the way for smarter factories that leverage automation and advanced data analytics. From integrating robotics and artificial intelligence to adopting sustainable practices, innovative industrial solutions are not just improving operational performance; they are redefining how we conceptualize production in the twenty-first century. By embracing these advancements, manufacturing entities can not only remain competitive in a rapidly changing environment but also contribute to a more sustainable future.

In the realm of modern manufacturing and automation, the emergence of innovative industrial solutions is reshaping the landscape and driving unprecedented progress. As industries face the dual challenges of increasing productivity and sustainability, these transformative strategies offer a pathway to enhanced efficiency and adaptability. This article delves into the various approaches and technologies that are revolutionizing traditional manufacturing processes, paving the way for smarter factories that leverage automation and advanced data analytics. From integrating robotics and artificial intelligence to adopting sustainable practices, innovative industrial solutions are not just improving operational performance; they are redefining how we conceptualize production in the twenty-first century. By embracing these advancements, manufacturing entities can not only remain competitive in a rapidly changing environment but also contribute to a more sustainable future.

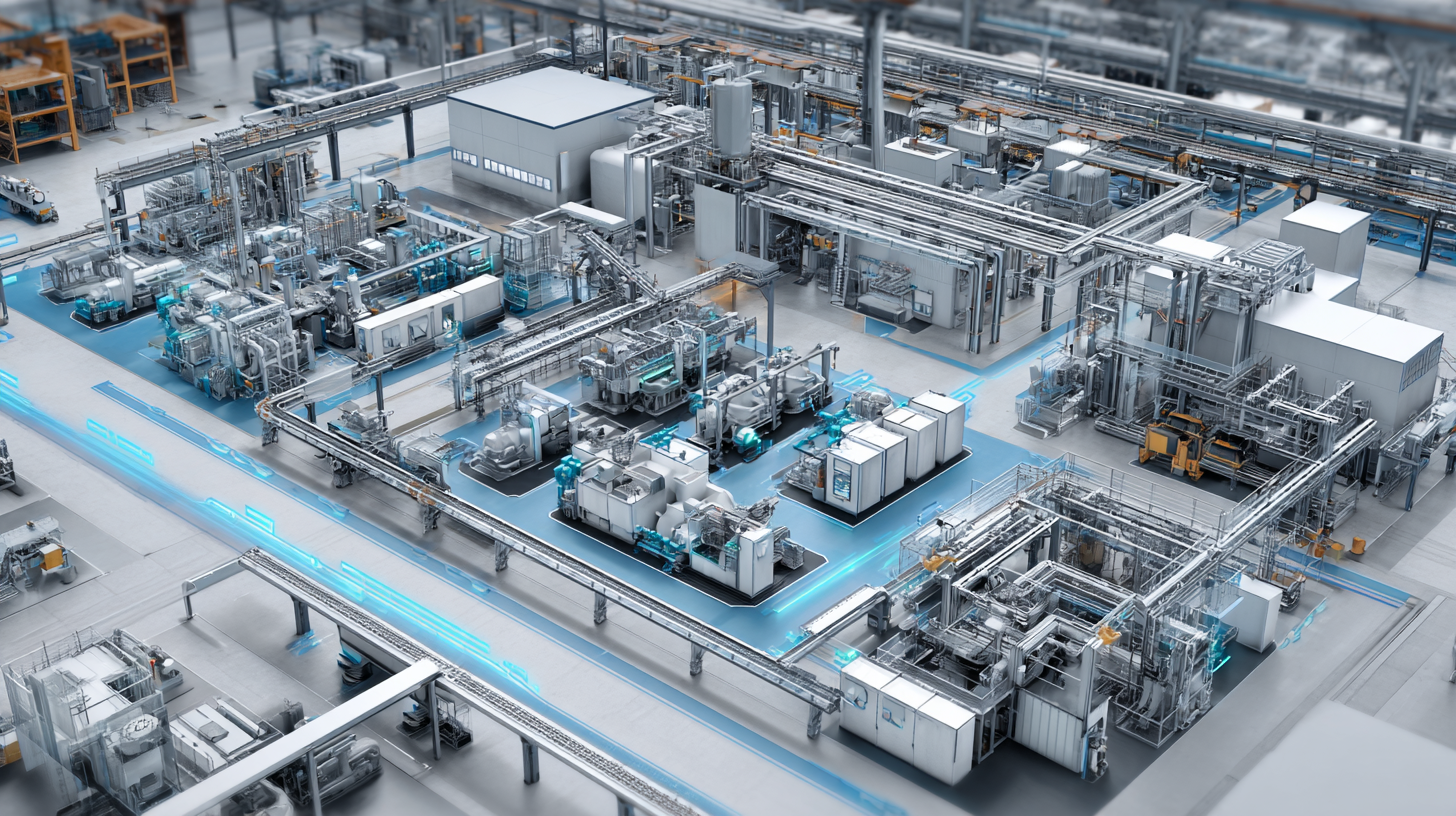

Innovative technologies are significantly reshaping manufacturing processes and efficiency metrics, driving industries towards greater productivity and sustainability. The integration of advanced automation systems and artificial intelligence allows manufacturers to optimize their workflows and minimize waste. Robotics, for instance, streamlines repetitive tasks, reducing labor costs while enhancing precision in production. This shift not only accelerates output but also improves product quality, as machines can operate consistently without the variability associated with human labor.

Moreover, the adoption of IoT (Internet of Things) in manufacturing enables real-time monitoring and data analytics, facilitating proactive decision-making. By harnessing vast amounts of data, manufacturers can identify bottlenecks, predict maintenance needs, and refine their operational strategies. This data-driven approach leads to enhanced efficiency metrics, allowing companies to measure their performance with greater accuracy and implement continuous improvements. As these innovative solutions emerge, they not only transform the manufacturing landscape but also pave the way for a more sustainable and responsive industrial ecosystem.

The integration of AI and machine learning into industrial environments is revolutionizing the manufacturing sector by creating smarter, more efficient systems. These advanced technologies enable machines to learn from data, adapt to changes, and optimize processes autonomously. For instance, AI-powered predictive maintenance allows manufacturers to anticipate equipment failures, reducing downtime and enhancing overall productivity. This shift towards data-driven decision-making empowers companies to streamline operations and minimize waste, transforming traditional manufacturing into a more agile and responsive model.

Moreover, AI and machine learning facilitate real-time monitoring and analytics, providing insights that can lead to improved quality control and enhanced safety measures. By analyzing vast amounts of operational data, these systems can identify anomalies and suggest corrective actions before minor issues escalate into significant problems. The result is a more resilient production environment that not only boosts efficiency but also promotes sustainable practices. As industries embrace these innovative solutions, the future of manufacturing and automation is poised for unprecedented growth and transformation, ultimately leading to smarter factories that harmonize productivity with environmental responsibility.

This chart illustrates the impact of integrating AI and machine learning in manufacturing automation, showcasing the percentage of companies implementing these technologies and their corresponding improvements in automation levels, productivity, and cost reduction.

The adoption of robotics within the global manufacturing landscape is undergoing a transformative shift, positioning itself as a critical driver of efficiency and innovation. According to the International Federation of Robotics, the deployment of industrial robots surged to approximately 3 million units globally by 2021, marking an increase of 14% compared to the previous year. This growth underscores a strong trend toward automation as businesses strive to enhance productivity and maintain competitiveness. Notably, the automotive, electronics, and metal industries exhibit the highest levels of robotic adoption, with manufacturing companies recognizing robotics as essential for meeting the demands of modern production environments.

Moreover, a report by McKinsey highlights that automation could raise productivity in manufacturing sectors by up to 30% by 2030. This potential increase in efficiency is prompting manufacturers to re-evaluate their operational strategies and investment priorities. The rise of collaborative robots, or cobots, is another noteworthy trend, with a market projected to grow at a compound annual growth rate (CAGR) of 36% from 2022 to 2028. These developments indicate that as industries continue to embrace innovative industrial solutions, the future of manufacturing will undoubtedly be shaped by the rapid advancement and integration of robotic technologies.

Sustainability practices in manufacturing have gained significant traction, with numerous innovations driving eco-friendly solutions across various sectors. According to a report by McKinsey & Company, implementing advanced sustainable practices can reduce manufacturing costs by up to 15% while also minimizing carbon footprints. Technologies such as additive manufacturing, often called 3D printing, are revolutionizing production processes by significantly reducing waste. This approach not only optimizes resource use but also enables manufacturers to produce complex designs with minimal environmental impact.

Moreover, the adoption of smart automation systems is contributing to greater sustainability. Research from the World Economic Forum indicates that integrating IoT and AI-driven technologies in manufacturing can decrease energy consumption by approximately 25%. These systems enhance predictive maintenance, thus prolonging equipment lifespan and reducing unnecessary waste. Additionally, the use of renewable energy sources in production lines is trending upward, with a report from the International Energy Agency suggesting that renewable energy accounted for over 30% of the global energy mix in 2020, a figure projected to reach 50% by 2030. As manufacturers continue to innovate and prioritize sustainability, they are not only improving their ecological impact but also achieving significant economic benefits.

The Internet of Things (IoT) is revolutionizing production and supply chain management by enabling real-time data exchange and automation. With IoT devices integrated into warehouse management systems, companies can achieve better asset tracking and inventory optimization. This technology streamlines operations, reducing manual errors and enhancing visibility across supply chains, which is crucial for responding to market demands efficiently.

As the logistics software market continues to evolve, the significance of IoT solutions becomes increasingly apparent. These tools are essential for managing complex supply chains in various sectors, including healthcare, automotive, and retail. By leveraging IoT capabilities, businesses can not only improve operational efficiency but also enhance decision-making through actionable insights drawn from comprehensive data analytics. This shift towards digitalization lays the foundation for innovative industrial solutions that will shape the future of manufacturing and automated processes.

| Parameter | Description | Impact | Technology Used |

|---|---|---|---|

| Predictive Maintenance | Monitoring equipment to predict failures before they occur | Reduces downtime and maintenance costs | IoT Sensors, Machine Learning |

| Real-time Inventory Management | Tracking inventory levels in real-time to minimize overstock and stockouts | Improves cash flow and operational efficiency | RFID, Cloud Computing |

| Supply Chain Visibility | Providing full visibility of the supply chain process to all stakeholders | Enhances collaboration and reduces delays | Blockchain, IoT Platforms |

| Energy Management | Optimizing energy consumption within the manufacturing process | Decreases costs and enhances sustainability | Smart Meters, IoT Analytics |

| Automated Quality Control | Using IoT devices to monitor and ensure product quality during production | Reduces defects and increases customer satisfaction | Cameras, Machine Vision Systems |

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources