In recent years, the market for precision tools has experienced a remarkable transformation, particularly with the rise of high-quality manufacturing in China. As we approach 2025, several industry trends highlight how technological advancements and quality upgrades are propelling the sales growth of these essential tools. The focus on innovation and precision engineering has led to the development of superior products that not only meet but often exceed global standards. This blog will explore the key technological trends shaping the precision tools industry, along with practical insights on how businesses can leverage these advancements to enhance their offerings and drive success in an increasingly competitive landscape. By understanding these dynamics, companies can position themselves effectively to capitalize on the growing demand for top-tier precision tools worldwide.

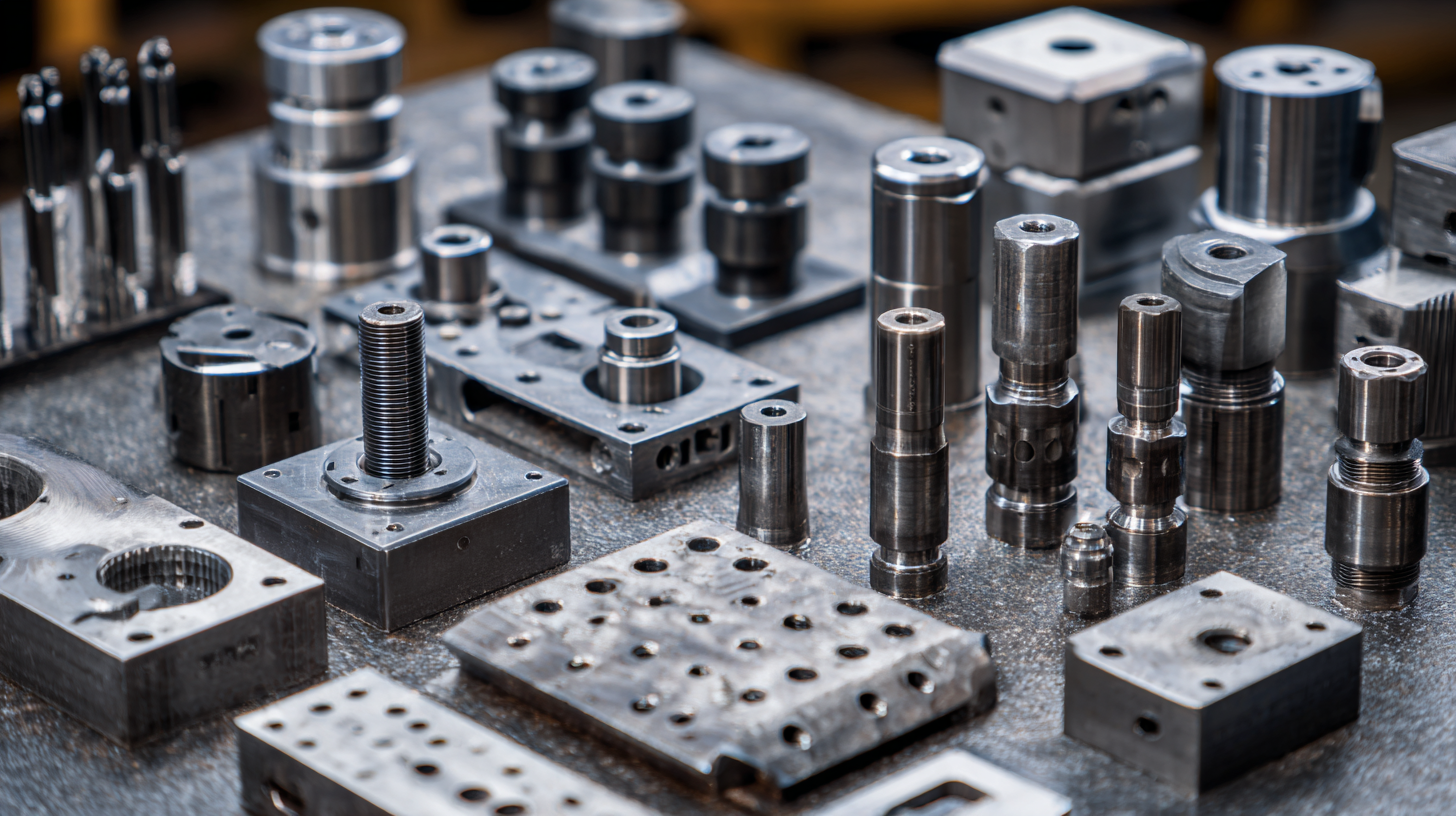

The global precision tools market is experiencing significant growth, fueled by enhanced quality and innovation from Chinese manufacturers. Precision tools from China are becoming increasingly competitive, leading to broader applications across various industries. From precision gearboxes to measuring instruments, these tools are gaining a reputation for their reliability and performance in global markets.

As businesses seek to enhance their production efficiency, high-quality precision tools like linear guides and CNC machining equipment are essential. The precision gearbox market is also seeing remarkable growth, projected to reach nearly $3 billion in the coming years. Investing in advanced precision tools not only improves manufacturing processes but also ensures compliance with global quality standards.

Tips for choosing the right precision tools include understanding your specific application needs and assessing the quality certifications of the products. Additionally, consider the potential for customization based on your operational requirements, which can lead to better outcomes in performance and efficiency. Make informed decisions by evaluating supplier capabilities and their commitments to quality upgrades in their product lines.

The precision tool industry has witnessed remarkable growth in recent years, largely driven by innovative quality upgrades. According to the latest market analysis from Grand View Research, the global industrial tools market, including precision tools, is projected to reach USD 172.74 billion by 2027, expanding at a compound annual growth rate (CAGR) of 6.8%. This surge is heavily influenced by advancements in manufacturing processes and materials, resulting in higher durability and precision in tools produced in China.

Leading Chinese manufacturers have embraced cutting-edge technologies, such as artificial intelligence and advanced robotics, to enhance their production capabilities. For instance, a report from Mordor Intelligence highlights that nearly 80% of major companies in the precision tools sector are investing in R&D to optimize tool performance and reliability. These quality upgrades have enabled Chinese tools to not only compete but excel in markets traditionally dominated by Western brands, thereby driving significant sales growth. As a result, the perception of Chinese-manufactured precision tools is shifting, emphasizing not just cost-effectiveness but also superior performance.

| Year | Sales Growth (%) | Quality Upgrade Type | Market Share (%) | Export Value (Million USD) |

|---|---|---|---|---|

| 2021 | 12 | Material Innovation | 35 | 150 |

| 2022 | 15 | Precision Process Enhancement | 40 | 175 |

| 2023 | 20 | Smart Technology Integration | 50 | 200 |

Precision tools play a crucial role in various industries, providing the accuracy and reliability needed for high-quality production. Among the key types of precision tools, calipers and micrometers stand out for their ability to measure dimensions with extreme accuracy.

Calipers, available in digital and analog forms, are ideal for measuring internal and external dimensions, as well as depths. These tools are essential in fields like machining and manufacturing, where even the slightest deviation can lead to significant issues.

Calipers, available in digital and analog forms, are ideal for measuring internal and external dimensions, as well as depths. These tools are essential in fields like machining and manufacturing, where even the slightest deviation can lead to significant issues.

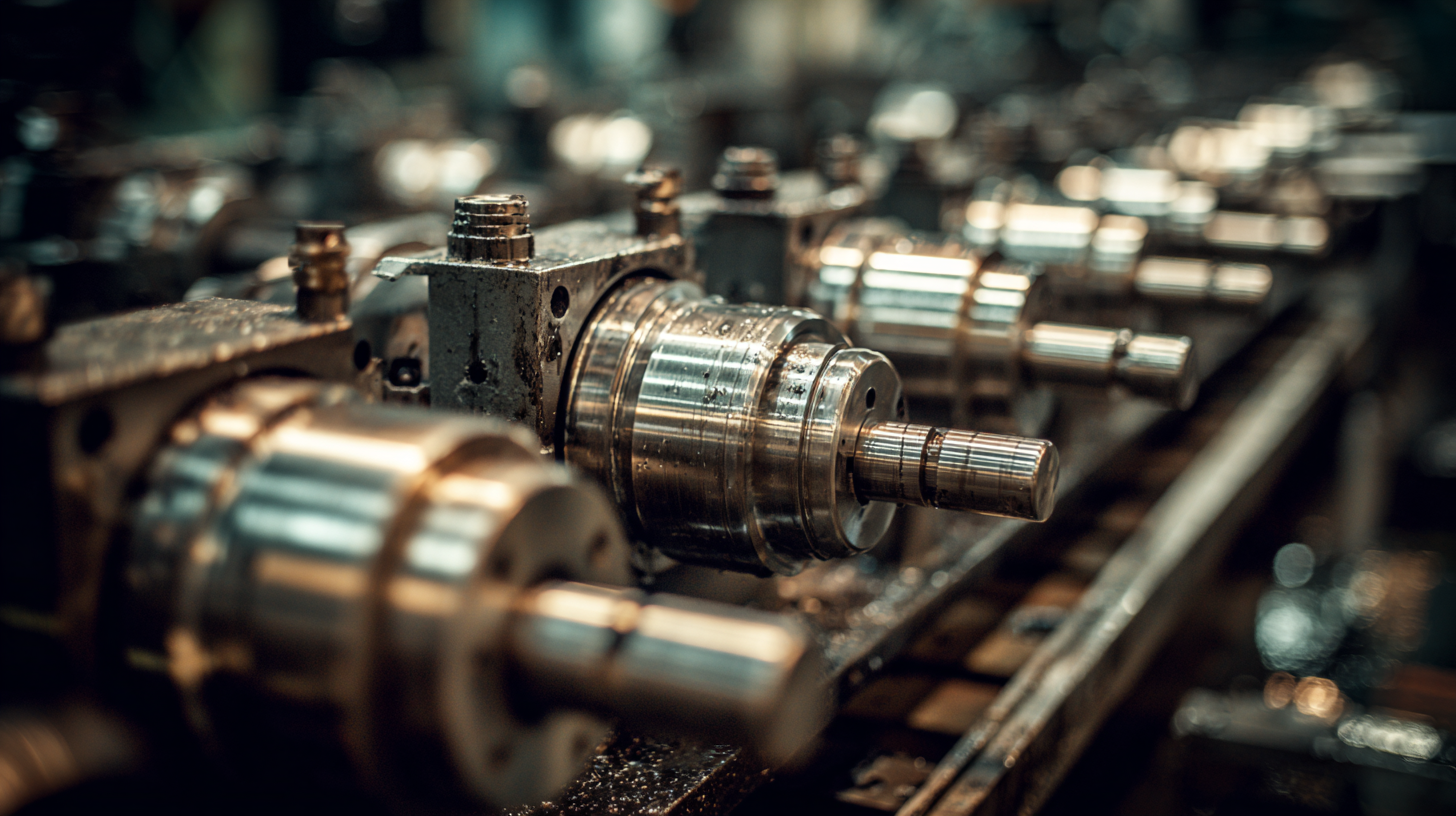

Another essential category of precision tools includes drilling machines and lathes, which are widely used in the woodworking and metalworking industries. Modern CNC (computer numerical control) machines have revolutionized precision drilling, delivering superior accuracy and speed. These machines can automatically adjust settings for different materials, enhancing productivity while minimizing human error. As manufacturers increasingly rely on these advanced tools, the demand for high-quality, precision-engineered products from China continues to rise, driven by innovations and improvements that align with global industry standards.

When selecting precision tools for various applications, it is essential to consider several key factors that can significantly affect performance and efficiency. According to a report from MarketsandMarkets, the global precision tools market is projected to reach $18.5 billion by 2025, with a compound annual growth rate (CAGR) of 4.8%. This growth is largely attributed to advancements in technology and heightened quality standards, particularly for tools manufactured in China.

It's crucial to assess the specific requirements of your application, including material types, tolerances, and operating conditions. For instance, CNC machining often requires tools that can withstand high speeds and temperatures, so selecting high-quality carbide or coated tools can enhance durability and precision. A tip for buyers is to always check for ISO certification on tools, which ensures they comply with international quality standards.

Moreover, consider the versatility of the tools. Investing in multi-functional precision tools can yield significant cost savings and adaptability for various projects. According to a study by Grand View Research, 60% of professionals prioritize versatility in their tool selection. An important tip is to consult with manufacturers or industry experts who can provide insights tailored to your specific applications, helping you to choose the right tools that align with both quality and performance expectations.

The precision tool manufacturing industry in China is poised for substantial growth by 2032, driven by quality upgrades and the adoption of advanced technologies. The market for precision tools is expected to expand significantly, with projections indicating a compound annual growth rate (CAGR) of over 7.5% during the upcoming decade. This growth is fueled by increasing demand across various sectors, including construction, manufacturing, and automotive, where high-precision tools are essential for maintaining competitive advantages and ensuring consistent quality in production processes.

In the context of broader industrial trends, China's push toward smart manufacturing and automation will heavily influence the precision tool market. As enterprises, both large and small, increasingly embrace innovative solutions, the demand for adaptive tools that can accommodate diverse manufacturing needs is set to rise. The integration of artificial intelligence into manufacturing processes will streamline operations, enhance efficiency, and ultimately drive the evolution of precision tool design. As a result, manufacturers are expected to invest in next-generation precision tools that not only meet current industry standards but also anticipate future technological advancements and applications.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources