In today's fast-paced construction industry, efficiency is paramount. The right tools can significantly impact project timelines and costs. A cutting in tool plays a vital role in enhancing precision and speed during construction tasks. According to industry reports, improper cutting tools can lead to up to 30% of project delays due to rework and inefficiencies.

With the advent of advanced cutting in tools, contractors can achieve cleaner and more accurate cuts. This not only minimizes material wastage but also ensures better adherence to design specifications. Yet, despite their importance, many teams still overlook the value of these tools. This can lead to frustrating slowdowns and project setbacks. A recent survey revealed that 65% of construction delays are attributed to inadequate preparation, including tool selection.

The cutting in tool is not just an accessory; it's essential for productivity. It caters to various applications, including drywall and flooring installations. Upgrading tools often means enhancing overall project quality. However, some professionals may resist change, fearing the learning curve. Reflecting on this could yield better outcomes and efficiency in the long run.

In the construction industry, cutting in tools are crucial for many projects. These tools ensure precise cuts in drywall, plaster, and other materials. Proper use of cutting in tools can dramatically enhance productivity. Research by the National Association of Home Builders (NAHB) shows that efficient cutting can save both time and labor costs by up to 15%.

Using a cutting in tool correctly offers benefits beyond just speed. It allows for clean edges and minimizes waste. A report from the American Builders and Contractors indicates that projects utilizing the right cutting tools experience 20% less material waste. This not only lowers costs but also supports sustainable construction practices.

Tip: Always inspect your cutting in tools before use. A dull blade can lead to inaccuracies and more material waste.

It's important to reflect on proper technique. Many workers overlook the angle of their cuts, leading to uneven finishes. This can delay a project and require additional work.

Tip: Practice on scrap pieces before starting on actual materials. This will help identify any areas for improvement.

| Dimension | Description | Usage Frequency | Advantages |

|---|---|---|---|

| Blade Type | Different blade types for various cutting needs. | Daily | Precision and versatility. |

| Material Compatibility | Compatible with wood, metal, and plastics. | Weekly | Ensures optimal performance based on material type. |

| Cutting Depth | Adjustable cutting depth for flexibility. | As needed | Allows for precise cuts and control. |

| Ease of Use | Designed for user-friendliness. | Daily | Reduces the learning curve for new users. |

| Durability | Made from high-quality materials for longevity. | Weekly | Long-term cost-efficiency due to fewer replacements. |

Cutting in tools play a crucial role in the construction process. These tools enable precise cuts, ensuring clean edges and accurate measurements. Without them, projects can face delays and costly mistakes. Builders often underestimate the importance of these tools. A minor error can lead to significant repercussions.

Using cutting in tools boosts efficiency on site. They help in various tasks, from installing drywall to flooring. The clean cuts facilitate easier fitting and faster installations. Wasted materials decrease, which is vital for budget management. However, many workers may neglect to use them regularly, resulting in subpar work.

Moreover, the safety aspect cannot be overlooked. Proper tools reduce the risk of accidents. Yet, some may opt for improper methods, risking injuries and delays. Training and experience are essential. Understanding the tools' capabilities enhances overall construction quality. Inadequate knowledge can lead to frustrating setbacks that could have been avoided.

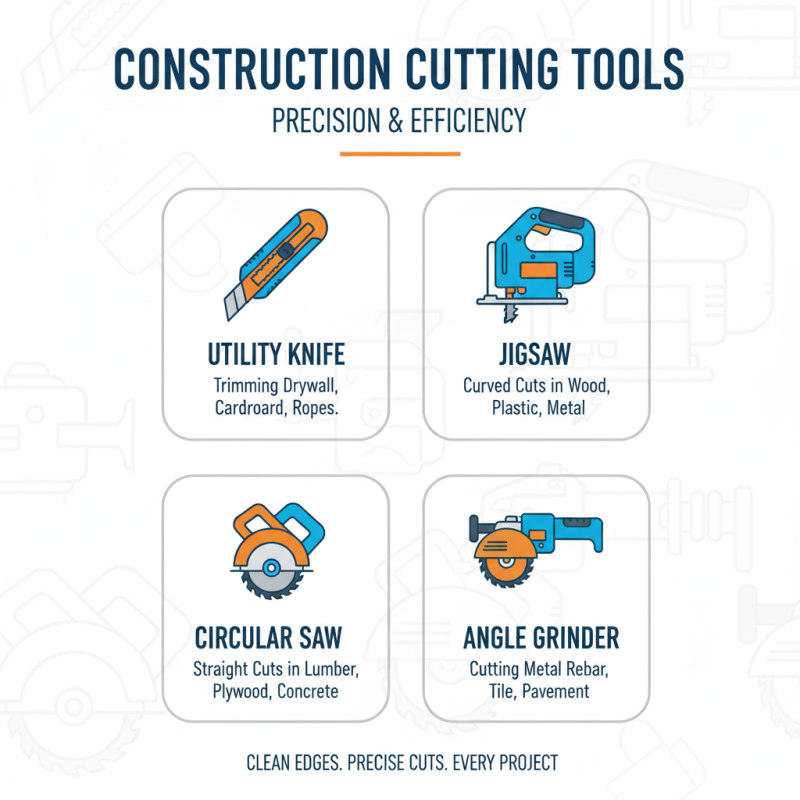

Cutting in tools play a vital role in construction. They help create clean edges and precise cuts. There are various types of cutting in tools, each designed for specific tasks. For instance, utility knives are perfect for trimming drywall, while jigsaws excel in curved cuts.

When choosing a cutting in tool, consider the material you'll work with. Wood, metal, and plastic all require different blades and techniques. Always remember to inspect your tools before use. A dull blade can lead to accidents and imprecise cuts. Replace blades regularly for safety and efficiency.

Tips: Keep your workspace organized. This reduces the chance of accidents. A clean area helps you find tools quickly. Also, practice cutting techniques on scrap materials first. This builds confidence and sharpens your skills. They say practice makes perfect, but even perfection needs review. Don’t hesitate to reassess your methods after each task.

Cutting in tools play a vital role in construction efficiency. They are designed for precision work, allowing builders to create clean lines and sharp edges. These tools enhance the quality of the finished project, making them indispensable.

When using cutting in tools, proper technique is crucial. Start by selecting the right tool for your specific task. For cutting sharp edges, a brush might be preferable. Ensure that your tool is clean and well-maintained. This will provide better performance and results over time.

Tips: Always practice on scrap material first. This helps refine your technique before tackling the actual job. Additionally, take breaks to avoid fatigue. A tired hand is prone to mistakes. Layer your paint or material gradually for better control and finishing. Maintaining a steady hand is key, even when you feel rushed.

The cutting in tool is evolving rapidly. Innovations are reshaping how professionals approach construction tasks. One fascinating trend is the integration of smart technology into these tools. According to a recent industry report, 42% of workers believe smart cutting tools will enhance efficiency on job sites.

Advanced materials are also on the horizon. Newer cutting blades are made with composite materials that show greater durability. These materials can withstand higher stress levels, reducing the need for frequent replacements. Interestingly, a survey found that 67% of construction professionals feel that longevity in tools directly impacts project timelines.

However, challenges remain. Many workers still lack training on these new technologies. The industry must address this gap to fully harness the benefits of innovations. Moreover, some cutting in tools are not yet user-friendly. Many find the adjustments complex, which can lead to frustration. The potential for improved design exists; feedback from workers could guide future iterations.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources