When selecting precision instruments for various applications, it is essential to consider both the specific needs of your projects and the capabilities of the available tools. The precision instruments market has seen significant growth, with projections indicating a compound annual growth rate (CAGR) of approximately 6.5% from 2021 to 2026, as reported by industry analysts. This growth is fueled by advancements in technology and the increasing demand for high-accuracy measurement solutions across sectors such as manufacturing, healthcare, and scientific research.

Investing in the right precision instruments can enhance operational efficiency and improve the quality of outputs, reducing errors and discrepancies in measurement. Reports indicate that inefficient measurement practices can lead to production losses of up to 20% in manufacturing environments, underscoring the importance of selecting tools that meet specific technical standards and precision requirements. As industries strive for higher accuracy and reliability, understanding the various types of precision instruments—ranging from calipers and micrometers to advanced digital measuring systems—becomes crucial for professionals aiming to meet industry benchmarks and client expectations effectively.

When selecting precision instruments, it is essential to understand the various types available and how they fit your specific needs. Precision instruments can broadly be categorized into measurement tools, calibration devices, and testing equipment. Measurement tools include calipers, micrometers, and laser measures, which are vital for obtaining accurate dimensions in manufacturing and engineering. Calibration devices, such as standards and gauges, ensure that measurements taken by other instruments remain precise, thereby maintaining quality and consistency across processes.

Another important category is testing equipment that evaluates performance and quality in a range of industries. Examples include electronic measurement instruments that gauge electrical properties and physical testing machines for assessing material strength or durability. Each type serves a distinct purpose, and the choice heavily depends on the specific application, required accuracy, and working environment. Understanding these fundamental differences will help in making informed decisions when it comes to selecting the right precision instruments for your particular applications.

When it comes to selecting precision instruments, the foremost step is to identify your specific measurement needs and requirements. Begin by evaluating the nature of your work: Are you performing quality control in manufacturing, conducting research in a laboratory, or perhaps working in field studies? Each scenario demands different types of instruments, so it’s crucial to define the context in which the measurement will occur. Key factors to consider include the range and resolution needed for accurate data, the environmental conditions in which the instruments will operate, and the required level of precision.

Additionally, consider the usability and calibration options of the instruments you plan to choose. If the measurement process is complex or if it involves multiple users, ensure that the instruments are user-friendly and come with clear instructions. Regular calibration and maintenance a necessity to sustain accuracy and reliability over time, so looking into these attributes will also help you make an informed decision. Ultimately, a careful analysis of your specific measurement needs will guide you in selecting precision instruments that not only meet your technical requirements but also contribute to greater productivity and efficiency in your work.

| Instrument Type | Measurement Range | Accuracy | Use Case | Recommended Environment |

|---|---|---|---|---|

| Caliper | 0-300 mm | ±0.02 mm | Precision measurements for small parts | Mechanical workshops, labs |

| Micrometer | 0-25 mm | ±0.01 mm | Measurement of thin materials | Controlled environments, labs |

| Digital Multimeter | 0-600 V | ±0.5% | Voltage, current, resistance measurements | Electrical workshops, fieldwork |

| Thermocouple | -200 to 1300 °C | ±1 °C | Temperature measuring in industrial applications | Manufacturing plants, laboratories |

| Pressure Gauge | 0-100 bar | ±0.5 bar | Monitoring pressure in systems | Pipelines, industrial systems |

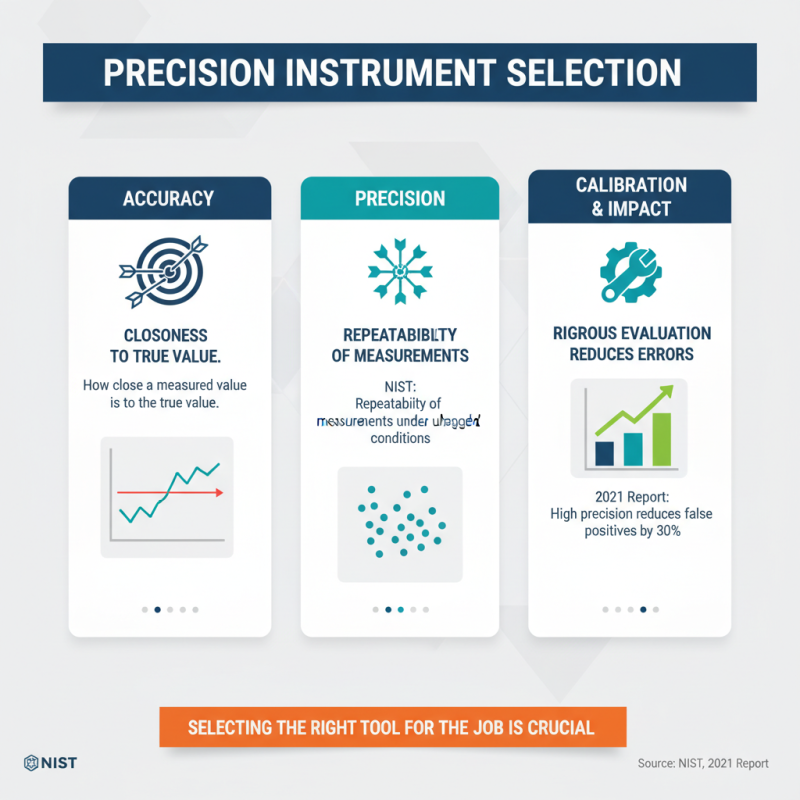

When selecting precision instruments, it is crucial to evaluate their accuracy, precision, and calibration rigorously. According to the National Institute of Standards and Technology (NIST), the accuracy of an instrument refers to how close a measured value is to the true value, while precision refers to the repeatability of measurements under unchanged conditions. A 2021 report highlighted that instruments with a higher precision rate, often evaluated through repeat tests, can reduce false positives in scientific measurements by up to 30%. Understanding these distinctions can significantly influence the selection process, ensuring the most suitable instrument is used for specific applications.

Calibration plays a vital role in maintaining the accuracy and precision of measurement instruments over time. The International Organization for Standardization (ISO) has outlined that regular calibration can enhance measurement reliability, with 65% of organizations reporting improved operational efficiency post-calibration. In many industries, such as pharmaceuticals, the need for stringent calibration protocols is paramount, driving compliance rates above 90% for regular instrument checks. By prioritizing these factors, users can select precision instruments that not only meet their specific needs but also stand the test of time through rigorous use and maintenance.

When selecting precision instruments, budget and cost-effectiveness are often at the forefront of decision-making. It's essential to analyze your specific needs and how they align with your available financial resources. Start by determining the essential features you require in an instrument—features that impact measurement accuracy, durability, and ease of use.

Balancing high-quality performance with affordability means not just looking at the initial purchase price, but also the long-term costs associated with maintenance, calibration, and potential upgrades.

Furthermore, consider the potential return on investment (ROI) when making your selection. Investing in a slightly higher-priced instrument that offers greater precision and reliability can lead to fewer errors, increased efficiency, and ultimately, reduced costs in the long run. Always weigh the immediate expenditure against the projected savings or additional revenue generated from improved operational quality. Cost-effective choices often involve thoroughly researching and comparing options, seeking out reviews, and understanding the total cost of ownership rather than just the sticker price.

When selecting precision instruments for your specific needs, conducting thorough research on manufacturers is crucial. Start by exploring the company's history, reputation, and specialization in the type of instruments you require. Look for manufacturers that have a proven track record of producing reliable and high-quality precision instruments. Attend trade shows or industry conferences where you can meet representatives and gain insights into their products and services. Additionally, consider the types of warranties and support they offer, as these can be indicators of the manufacturer's confidence in their products.

Reading reviews and testimonials from other users is another vital step in ensuring quality assurance. Online forums, professional organizations, and dedicated review websites can provide valuable insights into the performance and reliability of specific instruments. Pay attention to feedback regarding the accuracy, ease of use, and customer service experiences. Moreover, engage with industry peers to exchange information about their experiences with various manufacturers and instruments. This collective knowledge will empower you to make an informed decision that aligns with your operational needs and standards.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources