In the rapidly evolving landscape of manufacturing, the selection of the appropriate cutting machining technique is paramount for ensuring precision and efficiency in production processes. According to a recent report by the International Federation of Robotics, the global market for advanced cutting machining technologies is projected to reach $25 billion by 2025, driven by the increasing demand for automation and high-quality outputs across various industries. As companies strive to enhance productivity while minimizing waste, the ability to choose the right technique becomes a critical factor that directly impacts project outcomes.

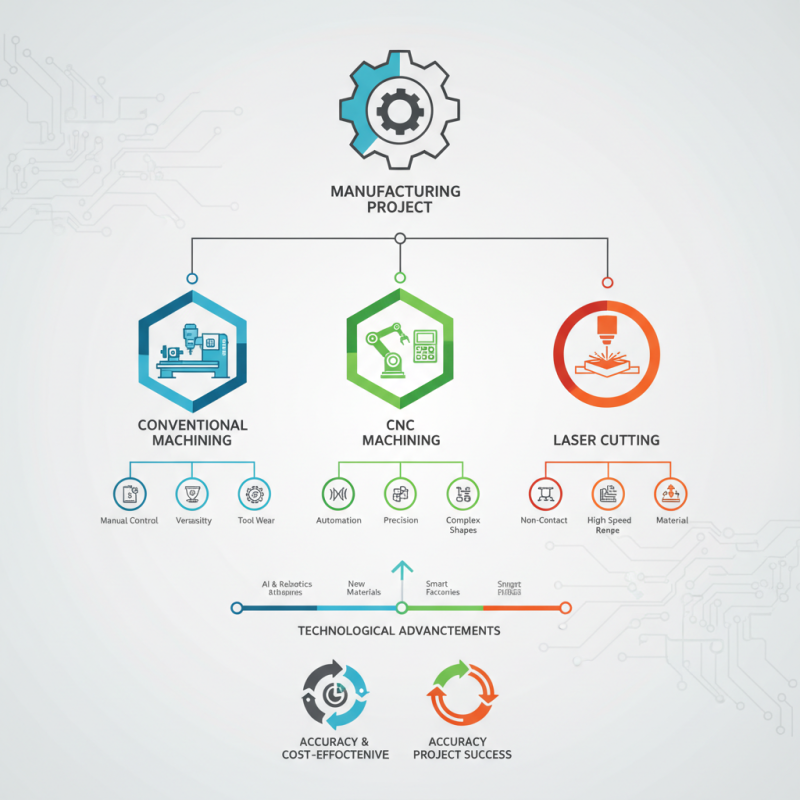

Expert insights from Dr. Michael Anderson, a leading authority in the cutting machining sector, emphasize the significance of this choice. Dr. Anderson states, "Selecting the correct cutting machining method can greatly influence the accuracy and cost-effectiveness of a project, making it essential for engineers and manufacturers to stay informed about the latest advancements." With various options available, including conventional machining, CNC machining, and laser cutting, understanding the unique advantages and limitations of each method is essential for optimizing performance and achieving desired specifications.

As we delve into the intricacies of cutting machining techniques in this article, it is crucial to consider not only the materials and desired tolerances but also the potential technological advancements that could redefine traditional practices. Armed with the right knowledge and guidance, industry professionals can make informed decisions that drive innovation and enhance overall project success.

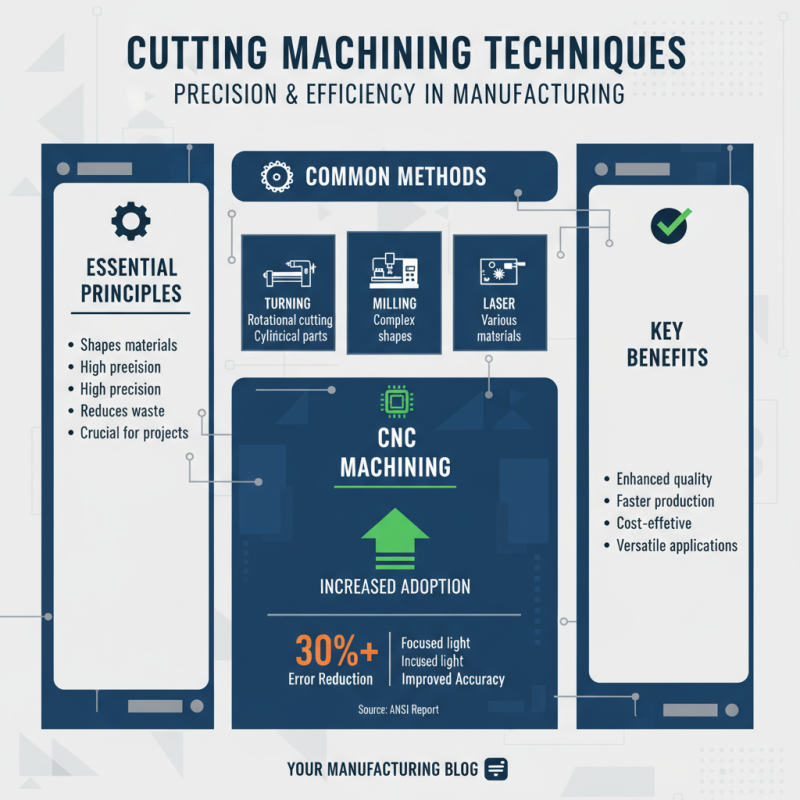

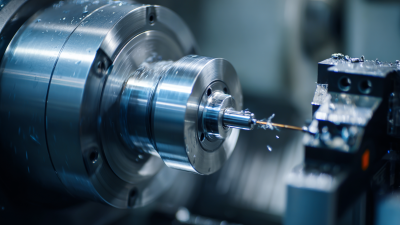

Cutting machining techniques are essential in manufacturing, providing precision and efficiency in shaping materials for various projects. Understanding the basic principles of these techniques is crucial for achieving the desired outcomes. Common methods include turning, milling, and laser cutting, each with unique attributes suited for different materials and applications. For instance, according to a report by the American National Standards Institute, CNC (Computer Numerical Control) machining has seen an increase in adoption rates, improving production accuracy and reducing error margin by over 30%.

When selecting a cutting technique, consider the material's properties, such as hardness and thickness. For softer materials like aluminum, traditional machining may suffice, while harder materials like titanium may require advanced techniques such as electrical discharge machining (EDM).

**Tips:** Always perform a feasibility study to compare the costs associated with each machining technique versus the expected quality and precision. Additionally, be mindful of compatibility issues between tooling and material types. Collaborating with experienced machinists can provide valuable insights into the best practices for your specific requirement, ensuring your project is completed efficiently and to high quality standards.

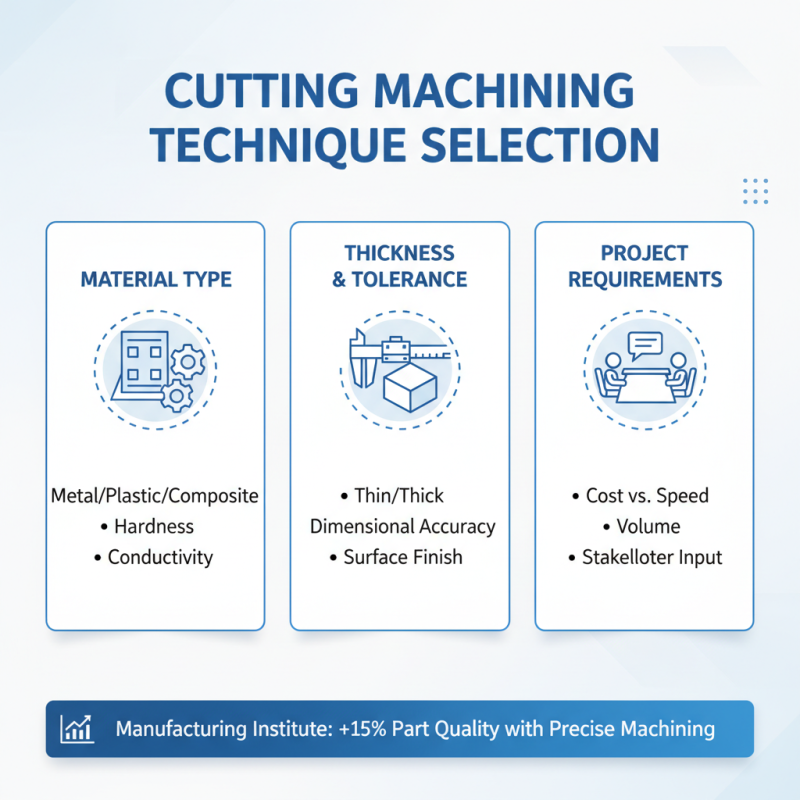

When selecting the right cutting machining technique for a project, several critical factors must be assessed to ensure optimal results. One of the primary considerations is the material type and thickness involved. For instance, a recent report by the Advanced Manufacturing National Program Office highlighted that different materials exhibit varying behaviors under mechanical stress, which significantly impacts the choice of cutting technique. For metals like aluminum and steel, methods such as laser cutting or waterjet cutting have shown to yield better precision and edge quality than traditional sawing methods due to their ability to handle intricate designs without damaging the material's integrity.

Additionally, the desired tolerances and finish quality play a pivotal role in decision-making. According to a study published in the Journal of Manufacturing Processes, achieving high tolerance levels often necessitates advanced techniques such as electrical discharge machining (EDM) or precision grinding. These methods not only provide tighter tolerances but also contribute to superior surface finishes, making them suitable for applications in aerospace and medical sectors where performance is paramount. Moreover, assessing production volume and lead time is essential; for high volume production, techniques like CNC machining can offer efficiency, while lower volume projects may benefit more from manual cutting methods to reduce setup costs.

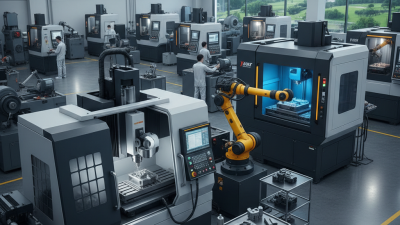

When selecting a cutting machining technique for a project, it's crucial to understand the various methods available, as each offers distinct advantages and limitations. One common method is traditional milling, which is ideal for producing complex shapes with high precision. Milling allows for effective material removal and is versatile enough to work with a wide range of materials, including metals and plastics. Its effectiveness is particularly noted in applications requiring detailed contours and a smooth finish.

Another popular technique is laser cutting, renowned for its speed and accuracy. This non-contact method utilizes laser technology to vaporize material, allowing for intricate designs and clean edges. Laser cutting is especially beneficial for thin materials and can handle complex geometries with minimal waste. However, it may not be the best choice for thicker materials or those that require significant strength.

Waterjet cutting is another option worth considering, particularly for materials that are susceptible to heat distortion. By using a high-pressure stream of water mixed with abrasive particles, this method achieves fine cutting while preserving the integrity of the material. It is suitable for a broad spectrum of materials, including metals, plastics, and glass, which makes it a versatile choice for diverse projects. Each of these techniques has unique capabilities, and understanding their differences can help in making the right choice for your specific project needs.

When selecting a cutting machining technique for a project, it is crucial to assess the compatibility of the material with the chosen method. Different materials possess unique properties that can influence the effectiveness and efficiency of various cutting techniques. For instance, metals like aluminum and steel may require specific techniques such as laser cutting or plasma cutting, which can accommodate their hardness and thickness. Conversely, softer materials like plastics may benefit from waterjet cutting or routing, which minimizes damage and ensures precision.

Understanding the material’s characteristics, including tensile strength, thermal conductivity, and brittleness, is essential in making an informed decision. Materials with high thermal conductivity may require techniques that reduce heat generation to prevent distortion, while brittle materials necessitate methods that reduce mechanical stress during the cutting process. By carefully aligning the material properties with the capabilities of different cutting techniques, manufacturers can enhance production efficiency and achieve superior results.

When selecting the appropriate cutting machining technique for a project, a thorough assessment of project requirements is essential. Factors such as material type, thickness, and desired tolerances significantly influence the choice of cutting method. For instance, a report from the Manufacturing Institute indicates that precise machining can improve part quality by up to 15%, making it critical to evaluate these variables upfront. Engaging stakeholders in detailed discussions can help clarify expectations from the project, ensuring that the selected method aligns with both manufacturing capabilities and end-user requirements.

TIPS: Clearly define project parameters, including material specifications and production volume, to streamline the decision-making process. This preparatory step can prevent costly adjustments later on and may lead to selecting techniques that enhance both efficiency and cost-effectiveness.

Additionally, consider the technological advancements in cutting techniques such as laser cutting and waterjet machining. These methods allow for intricate designs while minimizing material waste, which is increasingly becoming a priority in sustainable manufacturing practices. According to recent industry data, companies adopting advanced cutting technologies reported a 20% reduction in waste production. This demonstrates the significance of aligning project goals with modern machining capabilities to achieve optimal cutting solutions.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources