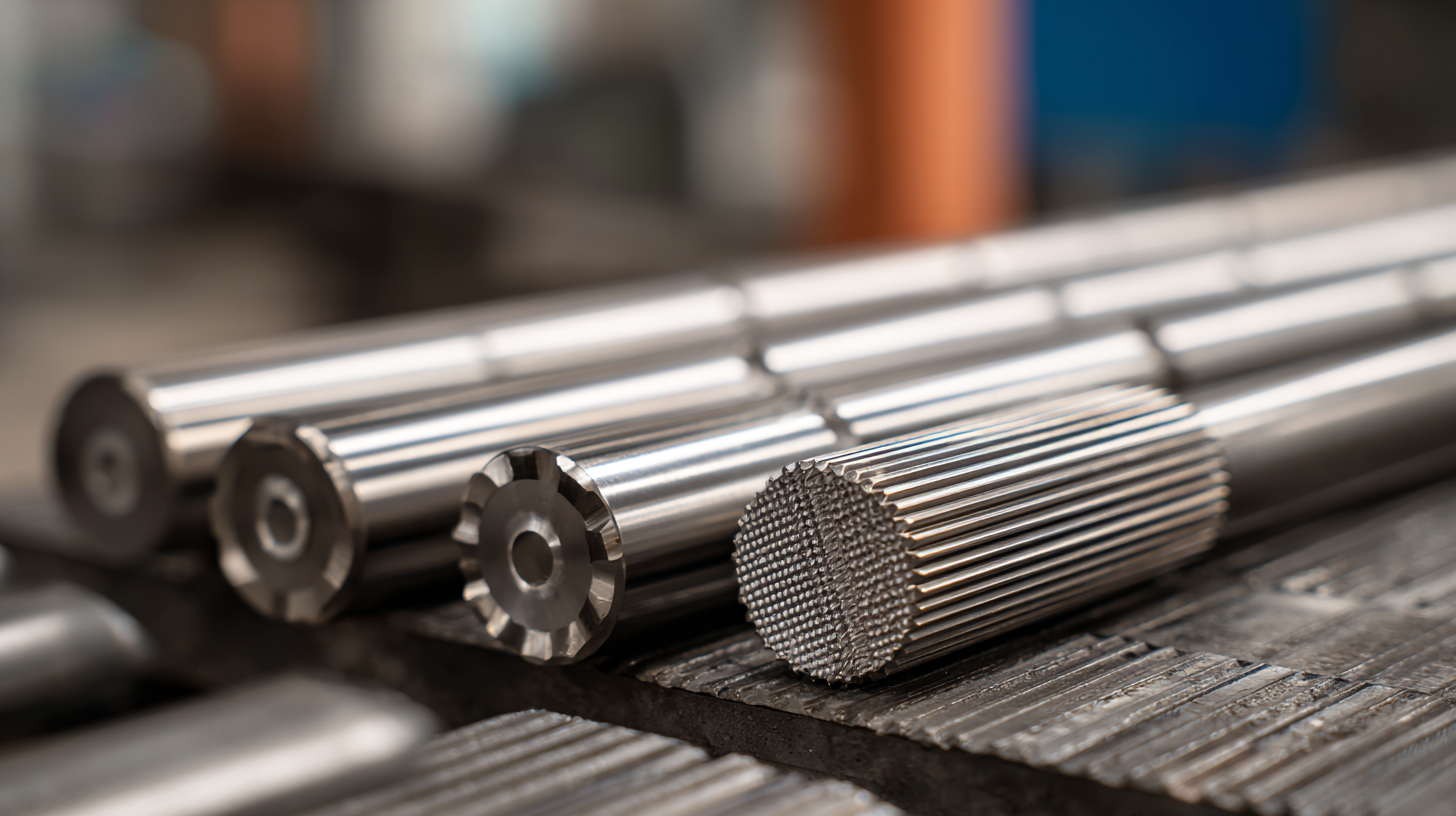

In modern manufacturing and engineering, carbide tools have become essential due to their unmatched hardness and wear resistance. According to a report by Global Industry Analysts, the carbide tools market is projected to reach $10.6 billion by 2025, driven by the increasing demand for precision machining across various industries, including aerospace, automotive, and metalworking. These tools, made primarily from tungsten carbide, exhibit remarkable performance characteristics that allow for higher cutting speeds and improved tool life compared to traditional materials. As industries continue to push the boundaries of efficiency and quality, innovations in carbide tools are pivotal in meeting these demands, enabling manufacturers to enhance production capabilities while reducing downtime and costs. This article delves into the technological advancements and diverse applications of carbide tools in contemporary industrial settings, shedding light on their critical role in advancing manufacturing processes.

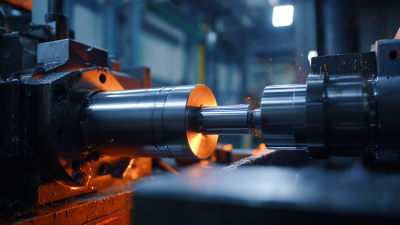

Carbide tools have revolutionized manufacturing efficiency across various industries, thanks to their exceptional hardness and wear resistance. According to a report from the Birmingham Business School, companies employing carbide tools have reported productivity gains of up to 30% in their machining processes. This increase is primarily due to the tools' ability to maintain sharper edges longer than conventional materials, which reduces the frequency of tool changes and minimizes downtime.

In modern manufacturing settings, the application of carbide tools extends beyond traditional machining. The Global Industry Analysts report indicated that the demand for carbide tools in sectors such as aerospace and automotive is projected to grow by over 6% annually, driven by the need for precision and durability in high-performance applications. The innovative use of carbide in cutting, grinding, and drilling operations not only enhances the quality of the final product but also significantly reduces operational costs, making it a critical component for manufacturers aiming to stay competitive in a rapidly evolving marketplace.

Recent advancements in carbide tool technology have significantly transformed precision engineering industries, yielding tools that deliver unparalleled performance and durability. A report from the International Tooling Association indicates that tools made from carbide can maintain their sharpness and structural integrity under extreme operating conditions, reducing downtime by 25% compared to traditional steel tools. This improvement enhances productivity and lowers overall manufacturing costs, making carbide tools an essential asset for modern engineers.

Moreover, innovations such as coated carbide tools have further increased cutting efficiency and tool life. Studies conducted by the American Society of Mechanical Engineers indicate that applying advanced coatings can improve wear resistance by up to 50%, allowing for longer machining cycles without the need for frequent tool replacements. These developments underscore the crucial role of carbide tools in precision applications across various sectors, including automotive and aerospace, where precision and reliability are paramount.

As industries continue to embrace these innovations, the demand for high-quality carbide tooling is expected to grow, alongside advancements in fabrication techniques that further enhance their capabilities.

Carbide tools have become essential in the aerospace and automotive industries due to their superior hardness and wear resistance. In aerospace applications, the demand for lightweight and high-strength materials makes carbide tools invaluable for precision machining and cutting. Their ability to maintain sharp edges under extreme conditions ensures consistent performance, which is critical in the manufacturing of components such as turbine blades and structural parts that require high accuracy and reliability.

In the automotive sector, carbide tools are widely utilized in the production of engine components and transmission parts. The rise of digital manufacturing technologies has further enhanced the capabilities of these tools, allowing for automation and improved precision in machining processes. This advancement not only increases productivity but also reduces waste, significantly contributing to the sustainability efforts within the industry. As manufacturing continues to evolve, the integration of carbide tools will play a pivotal role in meeting the complex demands of modern automotive and aerospace production.

Carbide tools have revolutionized the manufacturing landscape, offering significant advantages over traditional cutting tools made from high-speed steel (HSS) or other materials. One of the primary distinctions lies in the hardness and durability of carbide. With a Rockwell hardness significantly higher than that of HSS, carbide tools can withstand excessive wear and maintain a sharper cutting edge for longer periods. This reduces downtime for tool replacement and enhances overall productivity, making carbide the preferred choice in high-volume industrial applications.

In terms of performance, carbide tools excel in high-speed machining, resisting deformation under high temperatures that often affect traditional tools. They also offer better precision and finish quality, which is essential in industries such as aerospace and automotive, where tight tolerances are critical. The ability to use carbide tools at higher speeds without sacrificing quality or tool life translates to faster production rates and lower operational costs for manufacturers. Thus, while traditional tools remain suitable for less demanding jobs, carbide tools have established themselves as indispensable for modern industries that prioritize efficiency and precision.

The evolution of carbide tool design is being driven by advancements in materials science and engineering. Innovations such as nanostructured coatings and advanced carbide compositions are enhancing the performance of these tools. Manufacturers are focusing on improving wear resistance, toughness, and heat resistance to extend the lifespan of carbide tools, making them more efficient for industries such as aerospace, automotive, and metalworking. These materials are engineered at the molecular level, allowing for tailored properties that meet specific machining challenges.

In addition to improvements in material properties, production techniques are also undergoing significant transformation. Additive manufacturing, commonly known as 3D printing, is emerging as a viable method for producing complex carbide tools that were previously difficult or impossible to create using traditional methods. This technology not only reduces waste but also enables customization at scale. Moreover, automation and smart manufacturing systems are streamlining the production process, enhancing precision while minimizing human error. As these trends continue to develop, they will likely reshape the landscape of carbide tool applications, offering unprecedented possibilities for future industrial practices.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources