In today’s competitive manufacturing landscape, the precision and efficiency of machining processes have become crucial determinants of success. According to a report by Technavio, the global precision tools market is projected to grow by over 4% annually, highlighting the increasing demand for high-quality equipment such as SGS precision tools. These tools not only enhance productivity but also ensure that manufacturing processes meet stringent quality standards. As manufacturers strive for optimization, understanding the challenges associated with precision tools becomes pivotal. Efficient tool management and selection can significantly reduce waste and downtime, ultimately elevating the overall operational performance. This blog delves into the common issues faced with SGS precision tools and offers insightful tips to navigate these challenges, ensuring that businesses can achieve enhanced manufacturing efficiency in an ever-evolving industry.

Choosing the right SGS precision tools for your manufacturing needs is crucial for optimizing operational efficiency and maintaining high-quality standards. According to a recent industry report by Grand View Research, the global precision tooling market is expected to reach $12.7 billion by 2027, growing at a compound annual growth rate (CAGR) of 5.2%. This growth underscores the importance of selecting tools that not only meet the specific requirements of your manufacturing processes but also enhance productivity and reduce waste.

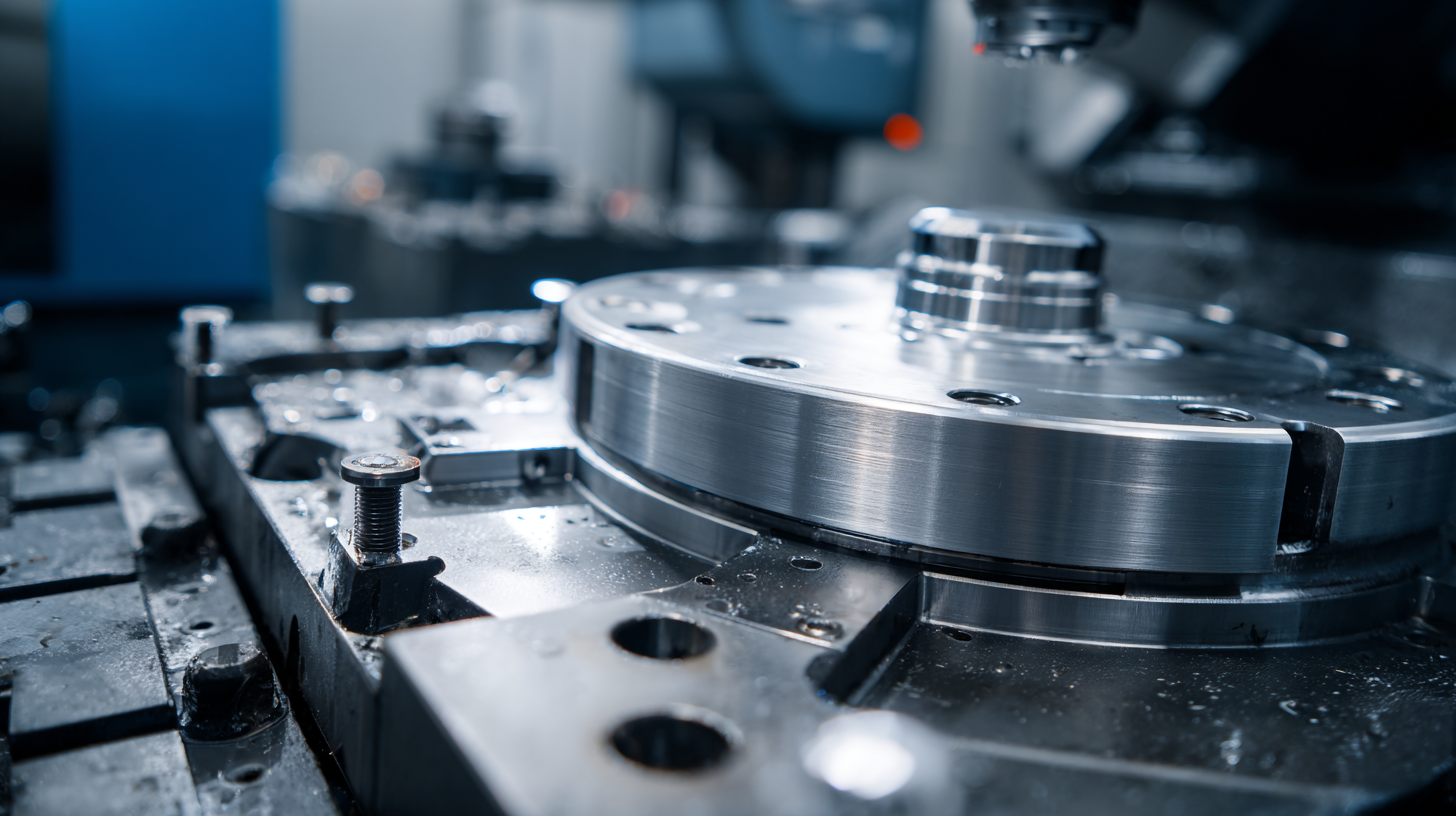

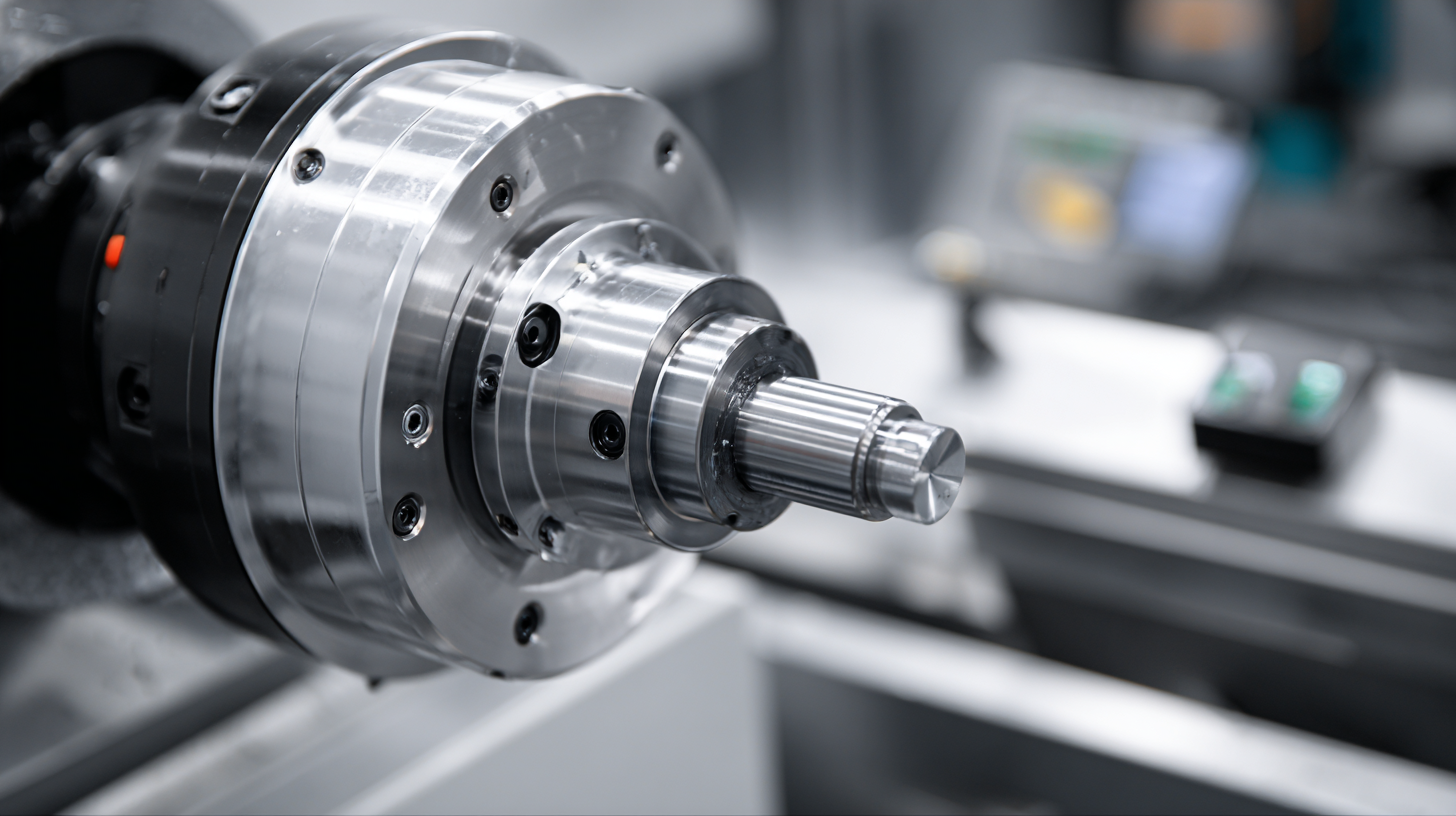

When assessing SGS precision tools, manufacturers should consider factors such as tool longevity, material compatibility, and precision levels. Tools designed with advanced coating technologies can significantly increase life expectancy and performance; for instance, studies show that carbide tooling can outperform standard steel tools by up to 30% in specific applications. Additionally, aligning tool selection with the latest manufacturing technologies—such as CNC machining and additive manufacturing—can further streamline production workflows. By making informed decisions based on comprehensive evaluations and industry insights, manufacturers can ensure that they are equipped with the best tools suited for their unique demands.

In the competitive landscape of manufacturing, the precision tool market is evolving rapidly, making it vital for manufacturers to understand the technical specifications of tools like those from SGS. According to a recent report from Grand View Research, the global precision tools market is expected to reach $40 billion by 2026, driven by increasing demand for high-quality manufacturing processes. Key specifications such as cutting speed, tool material, and coating technologies are critical for enhancing efficiency and ensuring product quality.

SGS precision tools stand out due to their high-performance carbide materials and advanced coating techniques, which significantly reduce friction and wear. For instance, tools equipped with PVD (Physical Vapor Deposition) coatings demonstrate up to 300% longer tool life compared to untreated tools. Additionally, the incorporation of geometric designs that optimize chip removal can lead to a 30% increase in machining speeds, thereby reducing cycle times. Understanding these specifications not only aids manufacturers in selecting the right tools but also ensures they stay competitive in an ever-evolving market.

| Tool Type | Material | Diameter (mm) | Length (mm) | Tolerance (mm) | Application |

|---|---|---|---|---|---|

| End Mill | Carbide | 10 | 50 | ±0.01 | Milling |

| Drill Bit | High-Speed Steel | 8 | 100 | ±0.02 | Drilling |

| Tapping Tool | Carbide | 5 | 60 | ±0.02 | Tapping |

| Reamer | Cobalt | 12 | 30 | ±0.03 | Finishing |

Efficient operation of SGS precision tools is essential for enhancing manufacturing productivity. To help you navigate the complexities of these tools, here’s a step-by-step tutorial to get you started. Begin by familiarizing yourself with the tool's specifications and features. Understanding their capabilities allows you to leverage them effectively to improve your processes.

Manufacturing faces numerous challenges, particularly when dealing with complex materials like aerospace grade carbon fiber. Understanding the most effective machining strategies is crucial for overcoming these hurdles, and precision tools play a vital role in this effort. By reducing cycle times and enhancing surface finishes, these tools can significantly increase manufacturing efficiency and product quality.

**Tip 1:** When selecting tools for composite machining, consider those specifically designed for the material. High-performance cutting tools optimized for carbon fiber can improve both efficiency and durability, preventing premature wear and the need for frequent replacements.

Moreover, effective leadership in manufacturers' organizations can help steer teams toward innovative machining solutions. Leadership transitions in tool companies provide fresh perspectives that can reshape strategies, ultimately benefiting manufacturers.

**Tip 2:** Stay informed about industry advancements and tool innovations; regular training and workshops can help ensure that your team is equipped to utilize the latest technologies effectively.

As manufacturers navigate their unique challenges, leveraging precision tools tailored for specific applications will undoubtedly lead to enhanced operational efficiency and competitive advantages in the marketplace.

In the realm of manufacturing, enhancing efficiency is not merely an aspiration but a necessity for maintaining competitiveness. According to a recent report by McKinsey, manufacturers that adopt advanced precision tools can increase productivity by up to 20%. SGS Precision Tools, renowned for their cutting-edge technology and superior quality, significantly contribute to this productivity boost. By selecting the right tools, manufacturers can achieve tighter tolerances and minimize material waste, which translates into cost savings and enhanced output.

Tip 1: Regularly evaluate your tool inventory to ensure alignment with current production needs. SGS offers a diverse range of precision tools tailored to various applications, allowing businesses to optimize their operations without investing in unnecessary equipment.

In addition to tool selection, implementing best practices such as routine maintenance can substantially improve manufacturing efficiency. A study from the National Institute of Standards and Technology (NIST) indicates that proactive maintenance can lead to a 25% increase in equipment lifespan and a 10% reduction in downtime. Investing in quality SGS tools and maintaining them regularly can create a more reliable manufacturing process, ensuring that production targets are consistently met.

Tip 2: Train your workforce on proper tool usage and maintenance. Proper training not only enhances safety but also maximizes the utilization of SGS Precision Tools, leading to better overall performance in the production environment.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources