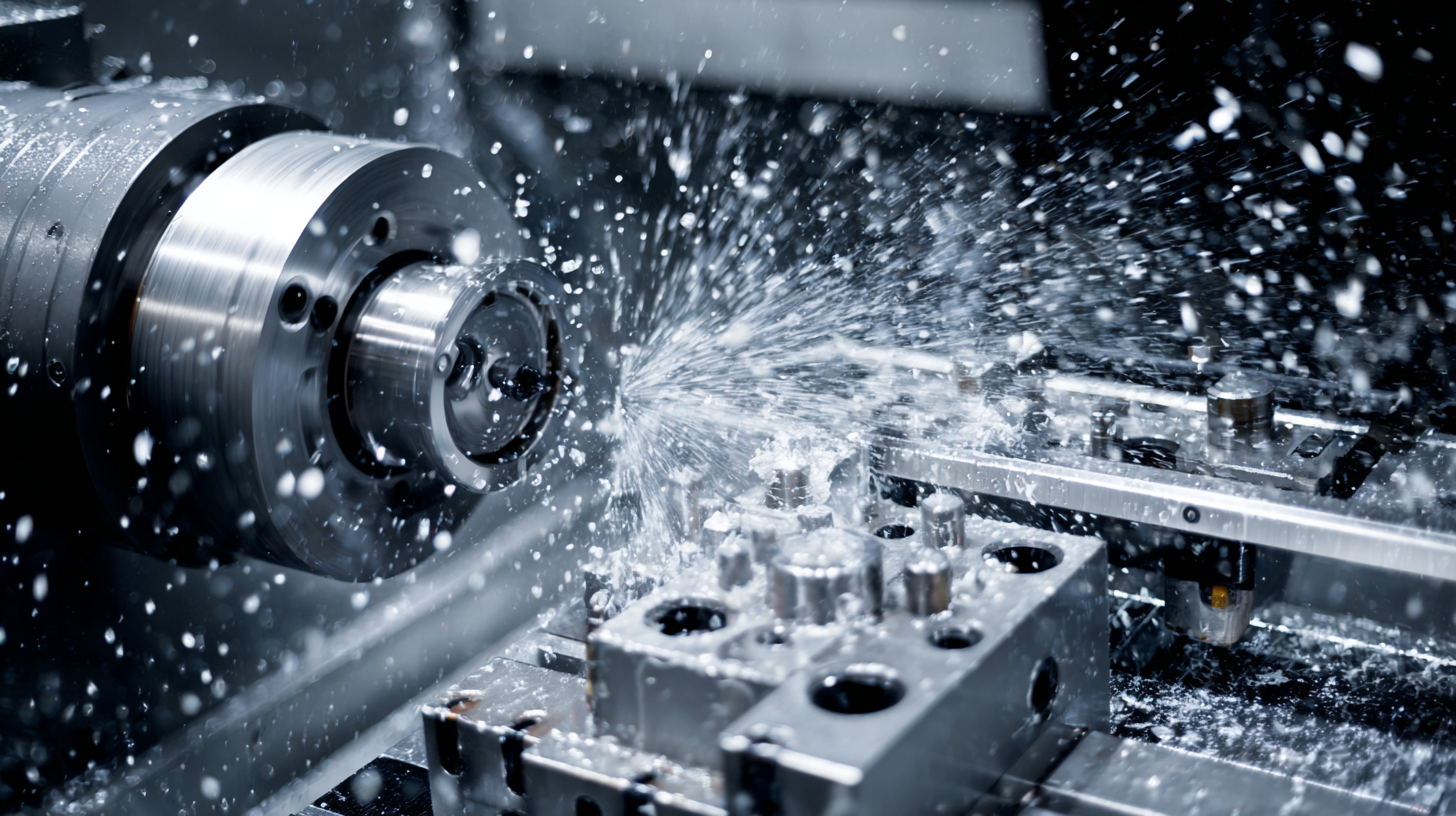

As we look ahead to 2025, the landscape of CNC machining is poised for significant transformation, driven by advancements in technology and shifting market demands. According to a recent industry report by Grand View Research, the global CNC machining market is expected to reach $100 billion by 2025, growing at a compound annual growth rate (CAGR) of 6.2%. This growth is largely attributed to the increasing need for precision manufacturing across various sectors, including aerospace, automotive, and healthcare. The integration of smart technologies such as IoT and AI is further revolutionizing CNC machining, enhancing efficiency and reducing production times.

As global buyers navigate these trends, understanding the evolving capabilities and applications of CNC machining will be crucial for staying competitive in an increasingly automated and interconnected industrial landscape.

As we approach 2025, the impact of artificial intelligence (AI) on CNC machining is becoming increasingly evident. The integration of AI technologies into CNC machining processes is set to significantly enhance efficiency and precision in manufacturing. One of the most exciting trends is the development of AI-powered machines that can optimize production workflows, predict maintenance needs, and reduce downtime. This technological shift is expected to propel the global CNC machine market, which is projected to grow from $101.22 billion in 2025 to $195.59 billion by 2032.

Tip: To leverage AI in your CNC operations, consider investing in training for your workforce. Understanding AI applications can help technicians make better use of these advanced tools and improve overall productivity.

Moreover, at trade events like EMO Hannover 2025, manufacturers are showcasing AI applications in machine tools, emphasizing the revolutionary changes on the factory floor. AI is not only redefining how machines operate but also enhancing the capabilities of skilled workers, who can focus more on complex tasks while machines handle repetitive and data-driven processes.

Tip: Stay updated on the latest AI technologies and innovations by attending industry expos and workshops. Networking with experts and peers will provide valuable insights into best practices and emerging trends in CNC machining.

The landscape of CNC machining is evolving rapidly, driven largely by advancements in material science. As we look towards 2025, the integration of artificial intelligence in material design and development is paving the way for innovative solutions in CNC processes. Tools such as MatterGen and MatterSim are at the forefront, enabling designers to create advanced materials that enhance the efficiency and precision of machining operations. These technologies streamline the journey from concept to creation, ensuring that materials are not only tailored for specific applications but also optimized for performance.

The landscape of CNC machining is evolving rapidly, driven largely by advancements in material science. As we look towards 2025, the integration of artificial intelligence in material design and development is paving the way for innovative solutions in CNC processes. Tools such as MatterGen and MatterSim are at the forefront, enabling designers to create advanced materials that enhance the efficiency and precision of machining operations. These technologies streamline the journey from concept to creation, ensuring that materials are not only tailored for specific applications but also optimized for performance.

Furthermore, innovations in material chemistry have significantly impacted industries like healthcare, particularly in the realm of contact lenses. These advancements illustrate the critical role that material science plays in developing products that meet evolving consumer needs. As CNC machining trends evolve, we can expect that the collaborative synergy between AI and material science will lead to more sustainable practices, increased automation, and enhanced product quality across various sectors. This transformative shift will be essential for global buyers aiming to stay competitive in an ever-changing market landscape.

As the CNC machining industry moves toward 2025, sustainability has become an imperative rather than an option. Recent reports indicate that the global CNC machining market is projected to reach $100 billion by 2026, with sustainable practices playing a crucial role in this growth. Buyers and suppliers are increasingly prioritizing eco-friendly methods, driven by a rising demand for products that reduce environmental impact. According to a study from the International Organization for Standardization (ISO), companies implementing sustainable machining practices can reduce energy consumption by up to 30%, significantly lowering their carbon footprint.

In addition to energy savings, the use of biodegradable lubricants and recycled materials is gaining traction among leading manufacturers. A 2021 report by Mordor Intelligence highlights that the adoption of green materials in CNC machining could decrease waste output by as much as 25%. These trends are not just beneficial for the planet; they also enhance a company's reputation and competitiveness in the market. As global buyers become more environmentally conscious, those who embrace sustainable CNC machining practices will not only meet current demands but will also set the stage for future success.

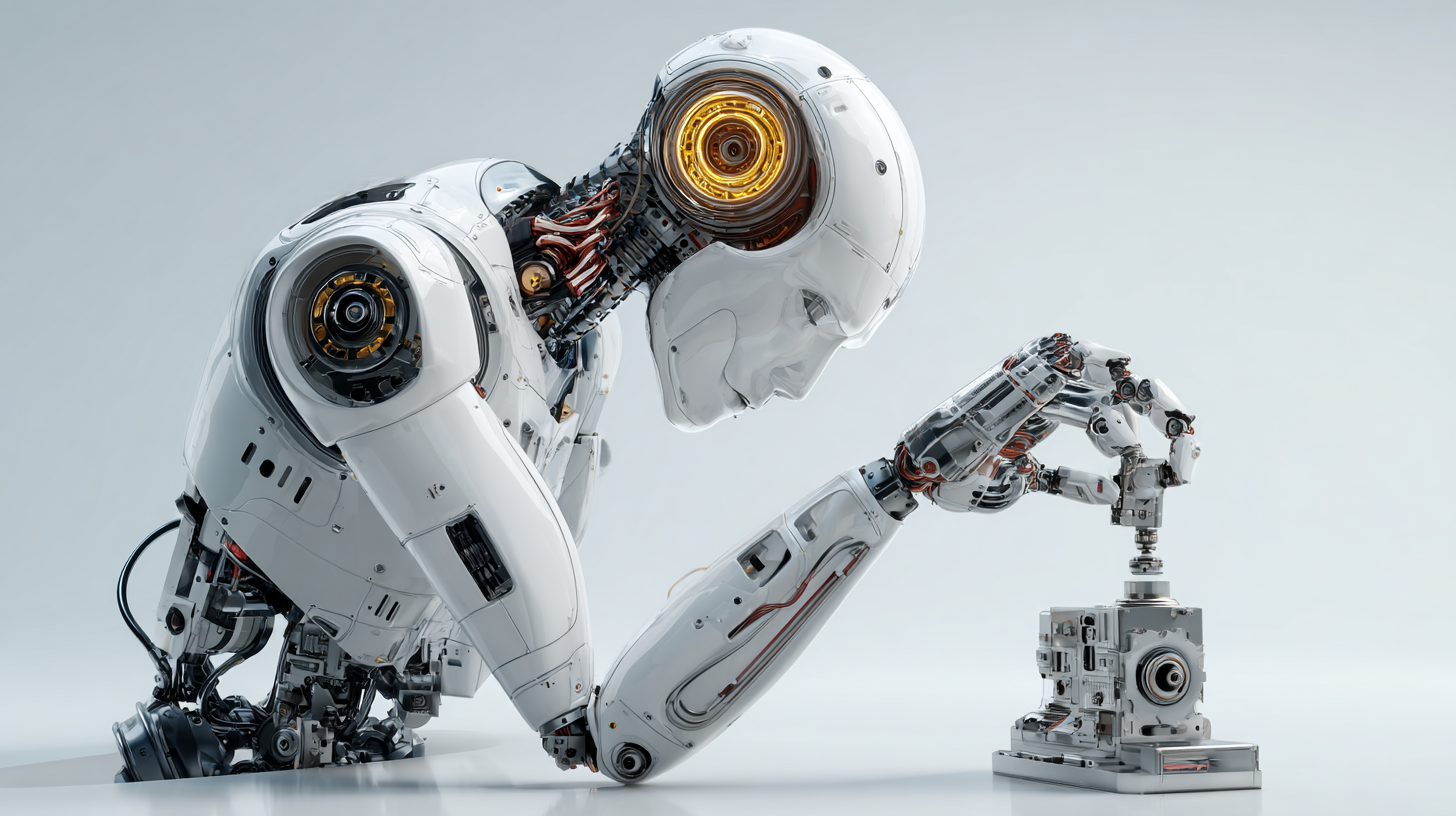

The rise of automation and robotics in CNC machining is poised to reshape the manufacturing landscape by 2025. As industries increasingly integrate robotic systems with CNC technology, we are witnessing significant improvements in process efficiency and productivity. Recent reports indicate that automation can reduce material handling time by up to 30%, leading to faster tool changes and streamlined operations. This not only enhances output but also optimizes the use of resources, making operations more cost-effective.

The growing trend toward incorporating collaborative robots (cobots) into CNC processes underscores the need for advancement in workforce adaptability. A study shows that 75% of manufacturers view robotics as essential for future competitiveness. Major players are showcasing their latest innovations at key industry events, emphasizing smart manufacturing solutions that leverage artificial intelligence and machine learning. With barriers to investing in CNC automation gradually diminishing, businesses are adopting these technologies to meet the rising demand for customized and efficient manufacturing capabilities. This is a crucial pivot for global buyers looking to stay competitive in an ever-evolving market.

As the CNC machining industry advances, data-driven decision-making becomes increasingly vital for manufacturers seeking to boost productivity and efficiency. Leveraging the power of the Internet of Things (IoT), companies can now gather and analyze real-time data from their machines, leading to actionable insights that significantly enhance operational performance. With interconnected devices, manufacturers can monitor various parameters, such as machine health, performance metrics, and production schedules, enabling proactive responses to potential issues before they escalate.

Moreover, the integration of IoT technology facilitates better resource management and inventory control. By utilizing data analytics, manufacturers can optimize workflow processes, reducing downtime and waste. This smart approach not only improves the overall production capacity but also contributes to a more sustainable operational model. As global buyers increasingly prioritize efficiency and reliability in CNC machining, embracing IoT for data-driven decision-making will be pivotal in staying competitive and meeting the evolving demands of the market.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources