As the manufacturing landscape continues to evolve, precision machining stands at the forefront of industry innovation, shaping the production processes across various sectors. According to a report by MarketsandMarkets, the global precision machining market is projected to reach USD 92.23 billion by 2025, growing at a CAGR of 8.5% from 2020 to 2025. This significant growth is driven by the increasing demand for high-quality and intricate parts in industries such as aerospace, automotive, and medical devices, where accuracy is paramount.

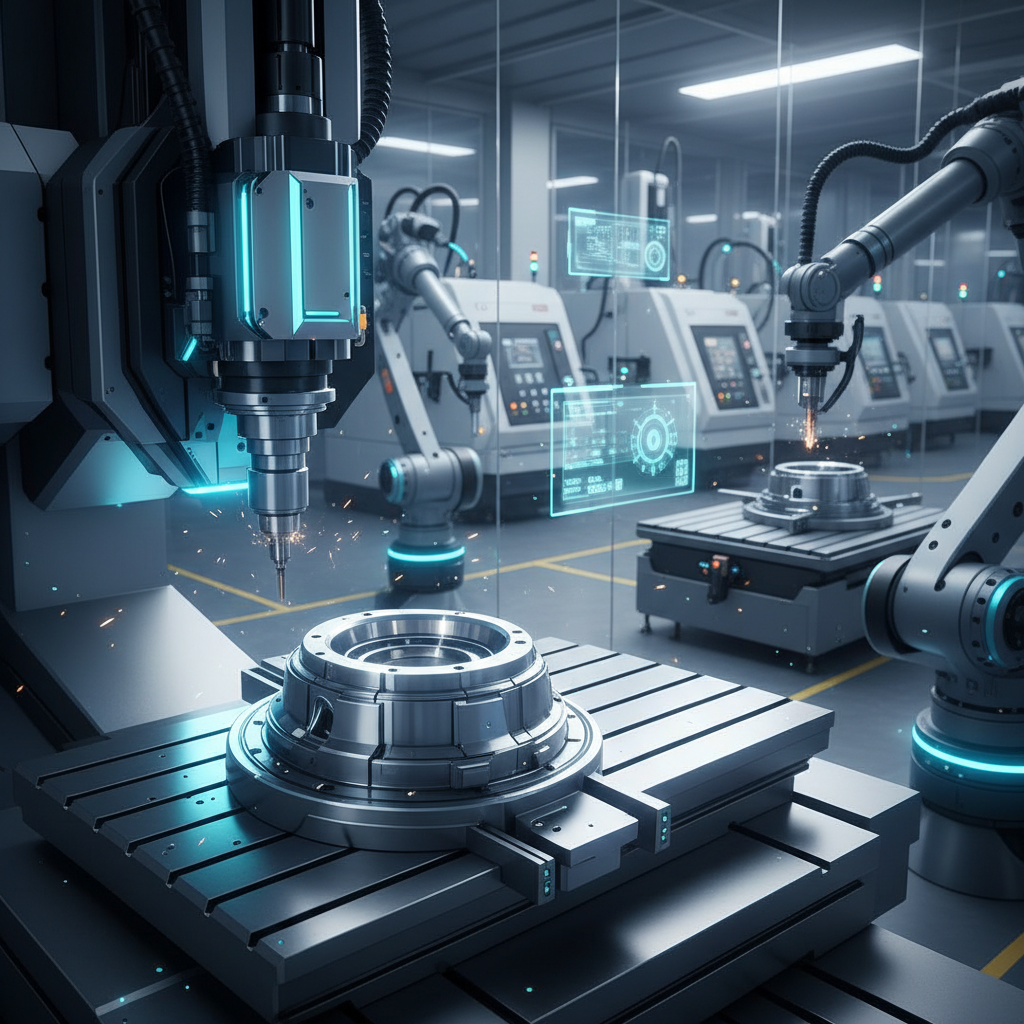

Looking ahead, the trends in precision machining are not just about enhancing productivity; they focus on integrating advanced technologies that transform traditional manufacturing methods. For instance, the rise of Industry 4.0 has paved the way for smarter factories, where the utilization of automation, IoT, and AI analytics enhances operational efficiency. The adoption of additive manufacturing also complements precision machining, allowing for the creation of complex geometries that were previously unattainable.

In this dynamic environment, staying ahead of the curve means embracing these trends. As we delve into the top five trends that will shape the future of precision machining by 2025, we highlight the critical innovations and practices that manufacturers must consider to maintain a competitive edge in an increasingly sophisticated marketplace.

Emerging technologies are profoundly reshaping the precision machining landscape, paving the way for enhanced efficiencies and innovative manufacturing solutions. According to a recent report by MarketsandMarkets, the global precision machining market is projected to reach $26.9 billion by 2025, growing at a CAGR of 6.8% from 2020. This growth is largely driven by advancements in automation and additive manufacturing, allowing manufacturers to achieve greater accuracy while reducing waste and production costs.

One notable trend is the integration of artificial intelligence (AI) and machine learning into machining processes. These technologies enable predictive maintenance, which minimizes downtime by forecasting equipment failures before they occur. A study by PwC indicates that AI can lead to a 20-30% increase in productivity in manufacturing settings. Additionally, the rise of IoT devices is facilitating real-time data collection, providing manufacturers with insights that drive continuous improvement and allow for greater customization of products. As these technologies evolve, precision machining will increasingly adapt, ensuring that manufacturers remain competitive in a rapidly changing market.

In recent years, sustainability has emerged as a pivotal focus in the realm of precision machining, significantly influencing modern manufacturing practices. Incorporating eco-friendly materials and energy-efficient processes, manufacturers are increasingly prioritizing environmental stewardship. The integration of renewable energy sources into machining operations not only reduces carbon footprints but also promotes long-term cost savings. This shift towards sustainability is not merely a trend; it’s an essential strategy for companies aiming to align with global environmental standards and consumer expectations.

Additionally, innovative waste reduction techniques are reshaping the way precision machining companies operate. Advanced machining technologies, such as additive manufacturing and closed-loop systems, enable the reuse and recycling of materials, minimizing waste generation. Furthermore, businesses are adopting sustainable sourcing practices that emphasize the use of recyclable materials and non-toxic lubricants, further contributing to a greener manufacturing landscape. As these practices become more standardized, they not only enhance operational efficiency but also pave the way for a more sustainable future in precision machining.

The manufacturing landscape is rapidly evolving, with automation and robotics taking center stage in precision machining. By 2035, the global market for rotary tables with torque motor drives is projected to exceed USD 340.6 million, highlighting the surge in demand for precision automation technologies. This growth reflects a shift towards more efficient and accurate production processes that can only be achieved through advanced robotics and automation systems.

Incorporating sophisticated technologies such as generative AI, innovative firms are redefining the capabilities of industrial robotics and CNC machining. Companies are now leveraging AI-powered software to enhance operational flexibility, making it easier to adapt to changing manufacturing demands. The integration of these technologies not only boosts productivity but also allows for significant cost savings, paving the way for more resource-efficient manufacturing solutions.

Tip: To ensure smooth integration of automation in your machining processes, consider taking incremental steps. Start by assessing your current machinery and identifying areas where automation can yield the highest returns.

Moreover, staying informed about the latest advancements in robotics, such as calibration systems and advanced kinematics, can play a crucial role in enhancing the precision of your operations. It’s essential to regularly evaluate new technologies that promise to bridge the gap between traditional machining and modern robotics for effective resource management.

Tip: Regular training for your workforce on new technologies will help in maximizing the benefits of automation while ensuring that your team is equipped to handle advanced machinery.

The integration of Data Analytics and the Internet of Things (IoT) is revolutionizing precision machining and manufacturing efficiency. As manufacturers harness these technologies, they are not only streamlining operations but also enhancing decision-making processes. The use of advanced data analytics allows for real-time monitoring of production lines, enabling companies to identify inefficiencies and rectify issues before they escalate. This proactive approach leads to reduced downtime and maximizes output quality.

Moreover, the global IoT in manufacturing market is experiencing significant growth, valued at $116.52 billion in 2024 and projected to reach $141.18 billion in 2025. This growth underscores the increasing reliance on connected devices and smart sensors that facilitate seamless communication between machinery and data analysis platforms. By leveraging IoT applications, manufacturers can gather extensive data on machine performance and operational metrics, which serves as a foundation for predictive maintenance and optimized resource allocation. As these trends evolve, the landscape of manufacturing will undoubtedly be shaped by the continuous advancements in data-driven strategies.

As the landscape of precision machining evolves, the need for a skilled workforce becomes increasingly critical. Talent development and skills training must adapt to meet the demands of advanced manufacturing technologies, including automation and additive manufacturing. Industries are now focusing on creating comprehensive training programs that blend theoretical knowledge with hands-on experience. These programs will equip employees with the skills necessary to operate sophisticated machinery and understand complex manufacturing processes.

Moreover, partnerships between educational institutions and industry leaders are essential for fostering a new generation of skilled workers. By collaborating on curriculum development, companies can ensure that training aligns with current market needs and technological advancements. This synergy not only helps in creating a talent pipeline but also encourages lifelong learning among employees. As precision machining continues to integrate digital technologies, ongoing professional development will be vital in maintaining a competitive edge in the manufacturing sector.

Contact

KYOCERA SGS Precision Tools, Inc.

(330) 686-5700

150 Marc Drive

Cuyahoga Falls, OH 44223

Products

Resources